Power Input Measurements in Stirred Bioreactors at Laboratory Scale

Summary

The power input in stirred bioreactors can be measured through the torque that acts on the impeller shaft during rotation. This manuscript describes how an air bearing can be used to effectively reduce friction losses observed in mechanical seals and improve the accuracy of power input measurements in small-scale vessels.

Abstract

The power input in stirred bioreactors is an important scaling-up parameter and can be measured through the torque that acts on the impeller shaft during rotation. However, the experimental determination of the power input in small-scale vessels is still challenging due to relatively high friction losses inside typically used bushings, bearings and/or shaft seals and the accuracy of commercially available torque meters. Thus, only limited data for small-scale bioreactors, in particular single-use systems, is available in the literature, making comparisons among different single-use systems and their conventional counterparts difficult.

This manuscript provides a protocol on how to measure power inputs in benchtop scale bioreactors over a wide range of turbulence conditions, which can be described by the dimensionless Reynolds number (Re). The aforementioned friction losses are effectively reduced by the use of an air bearing. The procedure on how to set up, conduct and evaluate a torque-based power input measurement, with special focus on cell culture typical agitation conditions with low to moderate turbulence (100 < Re < 2·104), is described in detail. The power input of several multi-use and single-use bioreactors is provided by the dimensionless power number (also called Newton number, P0), which is determined to be in the range of P0 ≈ 0.3 and P0 ≈ 4.5 for the maximum Reynolds numbers in the different bioreactors.

Introduction

Power input is a key engineering parameter for the characterization and scaling-up of bioreactors because it relates to many unit operations, such as homogenization1,2,3, gas-liquid dispersion2,4,5, heat transfer6 and solid suspension7. Power input is associated also with shear stress, which can particularly affect growth and product formation in shear sensitive cell cultures8,9,10,11.

The most common techniques for the measurement of the power input in stirred bioreactors are based on electrical power draw12,13,14, calorimetry12,15 (i.e. stationary heat balance or dynamic heating through the agitation) or the torque upon the agitator. The latter can be experimentally determined by dynamometers, torque meters or strain gauges, which have been applied for a variety of agitators, including single or multi-stage Rushton turbines1,16,17,18,19,20,21,22,23,24,25, pitched blade impellers19,20,23,26,27, InterMig19,21 and Scaba impellers28,29. A detailed review is provided by Ascanio et al. (2004)30.

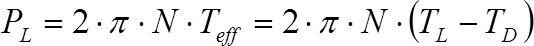

From the torque (T), the power input (P) can be estimated from Eq. 1, where N is the rotational speed of the agitator.

(1)

(1)

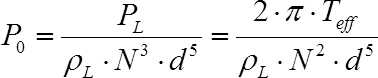

In order to account for losses occurring in the agitation (in bearings, seals and the motor itself), the effective torque (Teff) should be determined as the difference between the value measured in the empty vessel (TD) and in the liquid (TL). Finally, the dimensionless power number (P0, also known as Newton number), which is defined by Eq. 2 where ρL denotes the liquid density and d represents the impeller diameter, can be used to compare different agitators.

(2)

(2)

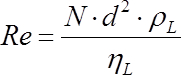

It is well-known that the power number is a function of the Reynolds number (i.e. the turbulence) and becomes constant under fully turbulent conditions. The impeller Reynolds number is defined by Eq. 3, where ηL is the liquid viscosity.

(3)

(3)

Nevertheless, power input measurements in small scale bioreactors are still challenging due to the relatively high friction losses inside mechanical bearings of the impeller shafts and the limited accuracy of most commercially available torque meters. Consequently, only a few reports about power input measurements in benchtop scale bioreactors have been published17,18,22,24,31,32. There is also a lack of data about the power input in single-use bioreactors, which are delivered by the manufacturers preassembled, sterilized and ready-to-use33,34. In contrast to their reusable counterparts, most single-use bioreactors are agitated by specially designed impellers, making comparisons difficult.

In order to close this gap, a reliable method for power input measurements with special focus on laboratory scale stirrers has been developed recently35. The torque values measured in the empty vessels, which were caused by the friction losses, were effectively reduced by the use of an air bearing. Consequently, a wide range of operational conditions with low to moderate turbulence (100 < Re < 2·104) could be investigated and the power input of several multi-use and single-use bioreactors has been provided.

The present study provides a detailed measurement protocol of the previously developed method and describes how to set up, conduct and evaluate a torque-based power input measurement in laboratory scale bioreactors. Special focus is on commercially available single- and multi-use systems. An automated measurement procedure is used to reduce the experimental effort.

Protocol

Representative Results

Discussion

Despite the importance of the (specific) power input for the engineering characterization and scaling-up/down of bioreactors, only a few publications on experimental investigations in benchtop scale bioreactors, particularly single-use systems in the one-digit liter volume range, can be found in the literature. One reason for this lack of data can be seen in the difficulties of accurate power input measurements in such small scales. In order to overcome some of these difficulties, the present study provides a detailed protocol for torque based power input measurements that are supported by an air bearing to minimize the friction losses in the bearing. The applicability of the method was demonstrated using three commercially available single-use bioreactors as well as multi-use bioreactors in scales between 1 L and 10 L working volume.

Based on our experience with the torque based measurements, the most critical factors to address are: 1) reducing the dead torque by minimizing the friction losses inside the bearings and seals, in particular in laboratory scale bioreactors, and 2) the selection of a suitable torque meter for the desired bioreactor size and agitation conditions. As has been shown earlier35, the dead torque can be dramatically reduced by the use of an air bearing. In the present study, a low cost air bushing made of porous carbon material was used. The residual torque in the empty vessels tested were typically below 0.5 mN·m with agitation rates of up to 900 rpm, corresponding to impeller tip speeds of up to 3 m·s-1. In contrast, the dead torque of the bioreactor #6 with the built-in mechanical shaft bearing was, for example, between 9.4 mN·m and 20 mN·m, and comparable values of around 3 mN·m have been also reported for the bioreactor #732. This is about one order of magnitude higher than the values obtained in the proposed experimental setup.

Besides the air bearing, the torque meter used is the most critical component. A commercially available torque meter that is designed for measuring static and dynamic torque, rotation speed and angle of rotation was selected for this study. Considering the bioreactors of interest with maximum working volumes of 10 L and the corresponding agitators, a nominal torque of 0.2 N·m was chosen. It was found that high reproducibility with relative standard deviation of replicates < 5% and reliable measurements can be obtained for effective torques as low as 2 mN·m, corresponding to only 1 % of the nominal torque. Hence, the measurement range of the sensor applied in the present study was significantly wider than results which have been published based on an inter-laboratory study of members of the German GVC-VDI working group on mixing41.

Nevertheless, the range of the agitator speed should be carefully selected with respect to the torque sensor resolution, the nominal torque and vortex formation. The latter often occurs in unbaffled bioreactors agitated at higher speeds and can cause damage to the torque meter. Both the minimum and maximum feasible agitator speeds can be limiting factors of the method described in this study. In addition to our previous work35, this study involved also the bioreactor #3, the smallest member in glass bioreactor family provided by the manufacturer, which is agitated by two-stage impellers with diameters of 42 mm. A comparable power characteristic to that in the geometrically similar bioreactor #4 was obtained with the presented experimental setup. This is notable since the torque scales with M  d5 for a given liquid density, impeller geometry (i.e. power number) and rotational speed (see Eq. 1 and Eq. 2). Consequently, an approximately 40% lower impeller torque results from a 10% smaller impeller diameter, for example. Nevertheless, higher rotational speeds in the 1 L scale than in the 2 L scale were required during operation to resolve the produced torque with the available torque meter. Due to the built-in baffles of the bioreactor #3, no vortex formation was observed, but this can become an issue with unbaffled vessels. It should be emphasized that the constant offset in the power numbers that was found between the two scales could result from measurement inaccuracies caused by the limited sensor resolution (in addition to geometrical differences). Further investigations are required to draw final conclusions on the minimum scale at which the proposed setup is still feasible.

d5 for a given liquid density, impeller geometry (i.e. power number) and rotational speed (see Eq. 1 and Eq. 2). Consequently, an approximately 40% lower impeller torque results from a 10% smaller impeller diameter, for example. Nevertheless, higher rotational speeds in the 1 L scale than in the 2 L scale were required during operation to resolve the produced torque with the available torque meter. Due to the built-in baffles of the bioreactor #3, no vortex formation was observed, but this can become an issue with unbaffled vessels. It should be emphasized that the constant offset in the power numbers that was found between the two scales could result from measurement inaccuracies caused by the limited sensor resolution (in addition to geometrical differences). Further investigations are required to draw final conclusions on the minimum scale at which the proposed setup is still feasible.

Nevertheless, the same protocol was used for power input measurements in various glass vessels from different manufacturers with working volumes of between 1 L and 10 L in our laboratory. This highlights the transferability of the used method for the characterization of different bioreactor systems. The experimental effort could be reduced by automated measurements using the recipe management within the automation system provided by the control unit software and the automated data processing based on the universal Matlab language.

Further, it should be noted that, by using the sucrose containing, cheap Newtonian model media, a wide range of Reynolds numbers (100 < Re < 6·104), depending on the agitator and scale, was covered. It should be also emphasized that the lower limit of the turbulence range is usually irrelevant for animal cell cultures with water-like media, even if very low impeller speeds are used. However, significant increases in the broth viscosity, which results in turbulence damping, and even non-Newtonian behavior have been described for fungi- and plant cell-based cultures. For example, apparent viscosities in plant cultures of up to 400-fold compared to water have been reported42, which leads to much lower Reynolds numbers.

Finally, using the bioreactor #7 as a first case study, it has been demonstrated that the proposed experimental setup can be used to study the effect of design modifications on the power input at laboratory scale. In combination with rapid prototyping techniques, this can be a powerful tool for impeller design studies, which will form parts of future work.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors would like to thank Dieter Häussler and Beat Gautschi for their assistance during the experimental set up. We are also grateful to Caroline Hyde for English proof reading.

Materials

| T20WN torque meter | HBM Hottinger Baldwin Messtechnik GmbH |

Nominal torque 0.2 Nm | |

| Spider-8 | HBM Hottinger Baldwin Messtechnik GmbH |

HBM Spider8 is no longer available for sale. QuantumX DAQ system (especially the QuantumX modules MX840A and MX440A) are recommended. |

|

| Catman easy software | HBM Hottinger Baldwin Messtechnik GmbH |

Version 4.2.2 | |

| Air bearing | IBS precision engineering | 13 mm air bushing | |

| Stainless steel impeller shaft | Bioengineering AG | Shaft tolerance -0.0076 mm | |

| Brushless motor AKM2 | Kollmorgen | ||

| Metal bellow coupling | Uiker AG | ||

| Finesse RDPDmini control unit | Finesse, a part of Thermo Fisher Scientific | No longer supported (the replacement product G3Lab universal controller can be used) | |

| Sucrose | Migros Schweiz AG | Food grade | |

| Matlab software | Mathworks | Version R2017a | |

| Finesse μTruBio PC software | Finesse, a part of Thermo Fisher Scientific | Version 3.1 (no longer supported) | |

| SmartGlass 1L | Finesse, a part of Thermo Fisher Scientific | referred to as Bioreactor 1L in Table 2 | |

| SmartGlass 3L | Finesse, a part of Thermo Fisher Scientific | referred to as Bioreactor 3L in Table 2 | |

| SmartVessel 3L | Finesse, a part of Thermo Fisher Scientific | referred to as Single-Use 3L Bioreactor in Table 2 | |

| Mobius CellReady 3L | Merck Millipore | referred to as Cell Ready Single-Use 3L Bioreactor in Table 2 | |

| UniVessel SU 2L | Sartorius Stedim Biotech | referred to as Single-Use 2L Bioreactor in Table 2 |

References

- Shiue, S. J., Wong, C. W. Studies on homogenization efficiency of various agitators in liquid blending. Can. J. Chem. Eng. 62, 602-609 (1984).

- Zlokarnik, M. . Rührtechnik — Theorie und Praxis. , (1999).

- Ghotli, A. R., Raman, A. A. A., Ibrahim, S., Baroutian, S. Liquid-liquid mixing in stirred vessels: a review. Chem. Eng. Commun. 200, 595-627 (2013).

- Arjunwadkar, S. J., Sarvanan, K., Kulkarni, P. R., Pandit, A. B. Gas-liquid mass transfer in dual impeller bioreactor. Biochem. Eng. J. 1, 99-106 (1999).

- Hari-Prajitno, D., Mishra, V. P., Takenaka, K., Bujalski, W., Nienow, A. W., McKemmie, J. Gas-liquid mixing studies with multiple up- and down-pumping hydrofoil impellers: power characteristics and mixing time. Can. J. Chemical Eng. 76, 1056-1068 (1998).

- Wichterle, K. Heat transfer in agitated vessels. Chem. Eng. Sci. 49, 1480-1483 (1994).

- Angst, R., Kraume, M. Experimental investigations of stirred solid/liquid systems in three different scales: particle distribution and power consumption. Chem. Eng. Sci. 61, 2864-2870 (2006).

- Cherry, R., Papoutsakis, E. T. Hydrodynamic effects on cells in agitated tissue culture reactors. Bioprocess Eng. 1, 29-41 (1986).

- Chalmers, J. J. Shear sensitivity of insect cells. Cytotechnology. 20, 163-171 (1996).

- Ma, N., Mollet, M., Chalmers, J. J., Ozturk, S. S., Hu, W. -. S. Aeration, mixing and hydrodynamics in bioreactors. Cell Culture Technology for Pharmaceutical and Cell-Based Therapies. , 225-248 (2006).

- Chisti, Y., Flickinger, M. C., Drew, S. W. Shear Sensitivity. Encyclopedia of Bioprocess Technology. , 1719-1762 (2002).

- Oosterhuis, N. M. G., Kossen, N. W. F. Power input measurements in a production scale bioreactor. Biotechnol. Lett. 3, 645-650 (1981).

- King, R. L., Hiller, R. A., Tatterson, G. B. Power consumption in a mixer. AIChE J. 34, 506-509 (1988).

- Brown, D. E. The measurement of fermenter power input. Ind. Chem. 16, 684-688 (1997).

- Bourne, J. R., Buerli, M., Regenass, W. Heat transfer and power measurements in stirred tanks using heat flow calorimetry. Chem. Eng. Sci. 36, 347-354 (1981).

- Böhme, G., Stenger, M. Consistent scale-up procedure for the power consumption in agitated non-newtonian fluids. Chem. Eng. Technol. 11, 199-205 (1988).

- Reséndiz, R., Martínez, A., Ascanio, G., Galindo, E. A new pneumatic bearing dynamometer for power input measurement in stirred tanks. Chem. Eng. Technol. 14, 105-108 (1991).

- Distelhoff, M. F. W., Laker, J., Marquis, A. J., Nouri, J. M. The application of a strain gauge technique to the measurement of the power characteristics of five impellers. Exp. Fluids. 20, 56-58 (1995).

- Ibrahim, S., Nienow, A. W. Power curves and flow patterns for a range of Impellers in Newtonian fluids: 40 < Re < 5×10^5. Chem. Eng. Res. Des. 73, 485-491 (1995).

- Karcz, J., Major, M. An effect of a baffle length on the power consumption in an agitated vessel. Chem. Eng. Process. Process Intensif. 37, 249-256 (1998).

- Houcine, I., Plasari, E., David, R. Effects of the stirred tank’s design on power consumption and mixing time in liquid phase. Chem. Eng. Technol. 23, 605-613 (2000).

- Chen, Z. D., Chen, J. J. J., Gupta, B., Ibrahim, S. . A study of agitated gas-liquid reactors with concave blade impellers. , 43-56 (2000).

- Chapple, D., Kresta, S. M., Wall, A., Afacan, A. The effect of impeller and tank geometry on power number for a pitched blade turbine. Chem. Eng. Res. Des. 80, 364-372 (2002).

- Gill, N. K., Appleton, M., Baganz, F., Lye, G. J. Quantification of power consumption and oxygen transfer characteristics of a stirred miniature bioreactor for predictive fermentation scale-up. Biotechnol. Bioeng. 100, 1144-1155 (2008).

- Cudak, M. Hydrodynamic characteristics of mechanically agitated air – aqueous sucrose solutions. Chem. Process Eng. 35, 97-107 (2014).

- Kuboi, R., Nienow, A. W., Allsford, K. A multipurpose stirred tank facility for flow visualisation and dual impeller power measurement. Chem. Eng. Commun. 22, 29-39 (1983).

- Wu, J., Zhu, Y., Pullum, L. Impeller geometry effect on velocity and solids suspension. Chem. Eng. Res. Des. 79, 989-997 (2001).

- Amanullah, A., Serrano-Carreon, L., Castro, B., Galindo, E., Nienow, A. W. The influence of impeller type in pilot scale xanthan fermentations. Biotechnol. Bioeng. 57, 95-108 (1998).

- Saito, F., Nienow, A. W., Chatwin, S., Moore, I. P. T. Power, gas dispersion and homogenisation Characteristics of SCABA SRGT and Rushton turbine impellers. J. Chem. Eng. Japan. 25, 281-287 (1992).

- Ascanio, G., Castro, B., Galindo, E. Measurement of power consumption in stirred vessels – a review. Chem. Eng. Res. Des. 82, 1282-1290 (2004).

- Vilaça, P. R., Badino, A. C., Facciotti, M. C. R., Schmidell, W. Determination of power consumption and volumetric oxygen transfer coefficient in bioreactors. Bioprocess Eng. 22, 261-265 (2000).

- van Eikenhorst, G., Thomassen, Y. E., van der Pol, L. A., Bakker, W. M. Assessment of mass transfer and mixing in rigid lab-scale disposable bioreactors at low power input levels. Biotechnol. Prog. 30, 1269-1276 (2014).

- Eibl, D., Peuker, T., Eibl, R., Eibl, R., Eibl, D. Single-use equipment in biopharmaceutical manufacture: A brief introduction. Single-Use Technology in Biopharmaceutical Manufacture. , 3-11 (2010).

- Eibl, R., Kaiser, S., Lombriser, R., Eibl, D. Disposable bioreactors: the current state-of-the-art and recommended applications in biotechnology. Appl. Microbiol. Biotechnol. 86, 41-49 (2010).

- Kaiser, S. C., Werner, S., Jossen, V., Kraume, M., Eibl, D. Development of a method for reliable power input measurements in conventional and single-use stirred bioreactors at laboratory scale. Eng. Life Sci. 17 (5), 500-511 (2016).

- Nienow, A. W., Miles, D. Impeller power numbers in closed vessels. Ind. Eng. Chem. Process Des. Dev. 10, 41-43 (1971).

- Liepe, F., Sperling, R., Jembere, S. . Rührwerke – Theoretische Grundlagen, Auslegung und Bewertung. , (1998).

- Kaiser, S. C., Werner, S., Eibl, D., Eibl, R., Eibl, D. CFD as tool to characterize single-use bioreactors. Single-Use Technology in Biopharmaceutical Manufacture. , 264-279 (2010).

- Liepe, F. Verfahrenstechnische Berechnungsmethoden Teil 4: Stoffvereinigen in fluiden Phasen – Ausrüstungen und ihre Berechnung. VEB Deutscher Verlag für Grundstoffindustrie. , (1988).

- Kraume, M., Zehner, P. Experience with experimental standards for measurements of various parameters in stirred tanks: a comparative test. Chem. Eng. Res. Des. 79, 811-818 (2001).

- Werner, S., Greulich, J., Geipel, K., Steingroewer, J., Bley, T., Eibl, D. Mass propagation of Helianthus annuus suspension cells in orbitally shaken bioreactors: Improved growth rate in single-use bag bioreactors. Eng. Life Sci. 14, 676-684 (2014).