Strain Sensing Based on Multiscale Composite Materials Reinforced with Graphene Nanoplatelets

Summary

The integration of conductive nanoparticles, such as graphene nanoplatelets, into glass fiber composite materials creates an intrinsic electrical network susceptible to strain. Here, different methods to obtain strain sensors based on the addition of graphene nanoplatelets into the epoxy matrix or as a coating on glass fabrics are proposed.

Abstract

The electrical response of NH2-functionalized graphene nanoplatelets composite materials under strain was studied. Two different manufacturing methods are proposed to create the electrical network in this work: (a) the incorporation of the nanoplatelets into the epoxy matrix and (b) the coating of the glass fabric with a sizing filled with the same nanoplatelets. Both types of multiscale composite materials, with an in-plane electrical conductivity of ~10-3 S/m, showed an exponential growth of the electrical resistance as the strain increases due to distancing between adjacent functionalized graphene nanoplatelets and contact loss between overlying ones. The sensitivity of the materials analyzed during this research, using the described procedures, has been shown to be higher than commercially available strain gauges. The proposed procedures for self-sensing of the structural composite material would facilitate the structural health monitoring of components in difficult to access emplacements such as offshore wind power farms. Although the sensitivity of the multiscale composite materials was considerably higher than the sensitivity of metallic foils used as strain gauges, the value reached with NH2 functionalized graphene nanoplatelets coated fabrics was nearly an order of magnitude superior. This result elucidated their potential to be used as smart fabrics to monitor human movements such as bending of fingers or knees. By using the proposed method, the smart fabric could immediately detect the bending and recover instantly. This fact permits precise monitoring of the time of bending as well as the degree of bending.

Introduction

Structural health monitoring (SHM) has become increasingly important because of the need to know the remaining life of structures1-3. Nowadays, difficult to access locations, such as offshore wind plants, lead to higher risks in maintenance operations, as well as greater costs2-4. Self-sensing materials constitute one of the possibilities in the field of SHM due to their ability of self-monitoring strain and damage5.

In the case of wind turbines, blades are generally manufactured in glass fiber/epoxy composite materials, which are electrically insulators. In order to confer self-sensing properties to this composite material, an intrinsic electrical network susceptible to strain and damage needs to be created. During the last few years, the incorporation of conductive nanoparticles such as silver nanowires6,7, carbon nanotubes (CNTs)8-10, and graphene nanoplatelets (GNPs)11-13 has been studied to create this electrical network. These nanoparticles can be incorporated into the system as filler into the polymer matrix or by coating the glass fiber fabric14. These materials can be also applied to other industrial fields, i.e., aerospace, automotive and civil engineering5, and coated fabrics can be used as smart materials in biomechanical applications7,15.

Piezoresistivity of these sensors is achieved by three different contributions. The first contribution is the intrinsic piezoresistivity of the nanoparticles; a strain of the structure changes the electrical conductivity of the nanoparticles. However, the main contributions are changes in tunnel electrical resistance, due to modifications in distances between adjacent nanoparticles, and electrical contact resistance, because of variations in the contact area between overlying ones9. This piezoresistivity is higher when 2D nanoparticles are used as a nanofiller compared to 1D nanoparticles because the electrical network presents a higher susceptibility to geometrical changes and discontinuities, usually one order of magnitude superior16.

Due to the 2D atomic character17 and the high electrical conductivity18,19, graphene nanoplatelets have been selected in this work as the nano-reinforcer of multiscale composite materials in order to obtain self-sensors with enhanced sensitivity. Two different ways to incorporate the GNPs into the composite material are studied in order to elucidate possible differences in sensing mechanisms and sensitivity.

Protocol

1. Preparation of the Functionalized Graphene Nanoplatelet Filled Epoxy for Multiscale Composite Materials

- Disperse functionalized graphene nanoplatelets (f-GNPs) into the epoxy resin.

- Weigh 24.00 g of f-GNPs to achieve a 12 wt% of the final nanocomposite material inside a ductless fume hood.

- Add 143.09 g of the bisphenol A diglycidyl ether (DGEBA) monomer and manually mix it to achieve homogeneity.

- Disperse the f-GNPs into the monomer by a twostep method, which combines probe sonication and calendering processes20.

- Sonicate the mixture at 50% of the amplitude and a cycle of 0.5 sec for 45 min.

- Apply 3 cycles of calendering using a roller gap of 5 µm and increasing roller speed at each cycle: 250 rpm, 300 rpm and 350 rpm.

- Weigh the mixture of f-GNP/monomer after completing dispersion.

- Degas the f-GNP/monomer mixture under vacuum and magnetic stirring at 80 °C for 15 min.

- Weigh and add the hardener in a weight ratio of 100:23 (monomer:hardener) and manually stir until achieving homogeneity.

2. Coating of the Glass Fabric with Functionalized Graphene Nanoplatelet Filled Sizing (Suspension) for Multiscale Composite Materials

- Disperse functionalized graphene nanoplatelets into the sizing.

- Weigh 7.5 g of f-GNPs, the quantity needed to achieve a 5 wt%, into 142.5 g of solvent (sizing/distilled water specified in 2.1.2) inside a ductless fume hood.

- Prepare the mixture of the f-GNPs and the sizing diluted with distilled water (1:1 wt) inside the ductless fume hood. Once the distilled water has been added, perform the work outside the ductless fume hood.

- Disperse the GNPs by probe sonication for 45 min at 50% amplitude and a cycle of 0.5 sec.

- Coat the glass fabric with the f-GNP filled sizing.

- With scissors suited for fabric cutting, cut 14 layers of glass fabric with dimensions of 120 х 120 mm2 and then coat them with the mixture of f-GNPs and sizing (2.1.3) by dip coating (one immersion) using a dip coater in the f-GNP filled sizing.

- Dry the f-GNP coated glass fabric in a vacuum oven at 150 °C for 24 hr as indicated in the technical sheets provided by the manufacturer.

3. Manufacturing of Multiscale Composite Materials

- Manufacture f-GNP/epoxy composite materials.

- After degassing the mixture, keep the f-GNP filled epoxy resin under magnetic stirring at 80 °C for all the manufacturing process.

- Place the 14 layers of the glass fabric into an oven at 80 °C.

- Alternatively, place a layer of the f-GNP filled epoxy and a layer of glass fiber fabric (14 layers) sequentially by hand on a metallic plate using a de-airing roller after placing each glass fabric layer.

- Use scissors to cut and place the anti-adherent polymer film (120 х 120 mm2) on a steel plate.

- Apply a layer of the f-GNP/epoxy mixture on the anti-adherent polymer film with a brush. Place a layer of glass fiber fabric. Note the importance of covering the area of the f-GNP/epoxy region and alignment of the different fabric layers. Remove the air and compact the plies by using a de-airing roller.

- Repeat step 3.1.3.2 until completing all of the layers of the laminate.

- Apply a final layer of the f-GNP/epoxy mixture with brush and cover the laminate with another layer of anti-adherent polymer film.

- Once all the fabric layers have been piled up, cure the laminate in a hot plate press at 140 °C for 8 hr with increasing pressure up to 6 bars.

- Extract the cured laminate from the hot plate press.

- Manufacture f-GNP/glass fiber composite materials by vacuum assisted resin infusion molding (VARIM).

- Prepare the metallic plate where VARIM is going to be carried out.

- Clean the steel plate surface with acetone.

- Place anti-adherent polymer film onto the steel plate.

- Place the sequence of f-GNP coated glass fabric (14 layers with dimensions 120 х 120 mm2) onto the plate. Ensure that the layers of fabric are aligned visually and by touch.

- Seal the vacuum bag with sealant tape for the VARIM process and pre-heat the system at 80 °C in an oven.

- Degas the DGEBA monomer under vacuum and magnetic stirring at 80 °C for 15 min. Add the hardener in a weight ratio of 100:23 (monomer:hardener) and stir until achieving homogeneity.

- Add the epoxy resin at 80 °C with a vacuum pump connected to the vacuum bag with a polymeric tube until the glass fabric pile is totally filled by the epoxy resin and cure the laminate in an oven at 140 °C for 8 hr.

- Extract the cured laminate from the oven and remove the vacuum bag and auxiliary material.

- Prepare the metallic plate where VARIM is going to be carried out.

4. Preparation of the Samples for Strain Sensors Tests

- Machine samples (Computer Numerical Control – CNC milling machine) of multiscale laminates to the required dimension for flexural tests following the ASTM D790-0221 and cut glass fabric bands 10 mm in width in order to study the strain sensitivity of the f-GNP coated fabric.

NOTE: Samples are fixed onto the machining table with adhesive tape and machined using the following parameters: feed speed of 500 mm/min, idle speed of 5,000 min-1 and depth steps of 0.1 mm. - Carefully clean the surface of the machined samples with acetone to eliminate dust.

- Paint lines of silver (acrylic conductive paint) on the surface of the materials distanced 20 mm apart to minimize the electrical contact resistance and adhere copper wires to the wet silver lines as electrodes to facilitate the measurement of the electrical resistance during the tests.

NOTE: Electrical contacts are located on both surfaces: compression surfaces and tensile subjected surfaces. - Once the silver paint is dry, fix the electrical contacts with hot melt adhesive to avoid electrical contact detachment.

5. Testing the Strain Sensor

- Analyze the electrical behavior of sensors under flexural loads (three-point bending test).

- Measure the specimen's width and thickness with a caliper.

- Set the specimen in the mechanical test machine with the flexural test configuration.

- Set the test speed (controlled by strain) to 1 mm/min and the start position that defines the initial length of the specimen.

- Connect the electrical contacts to the multimeter. Measure the electrical resistance between each two adjacent electrical contacts as it is specified in Figure 1.

- Run flexural test and monitor the electrical resistance simultaneously in order to study variations due to the induced strain in the specimen.

- Repeat all steps for at least 3 specimens of f-GNP/epoxy and f-GNP/glass fiber composite materials to confirm the electrical behavior of the composite materials.

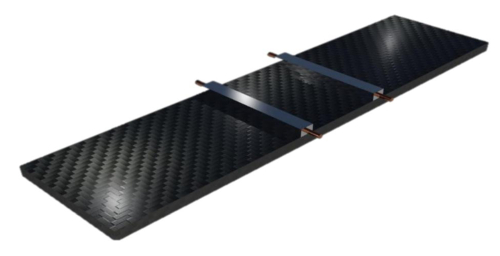

Figure 1. Electrical contacts setup in flexural tests of multiscale composite materials. Copper electrodes are attached on the surface of composite materials by using lines of silver paint (in gray) in order to minimize the electrical contact resistance. Please click here to view a larger version of this figure.

- Analyze f-GNP/glass fabric as strain sensors of human movements.

- Monitor finger bending.

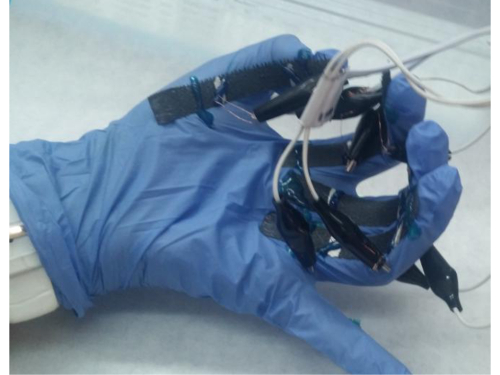

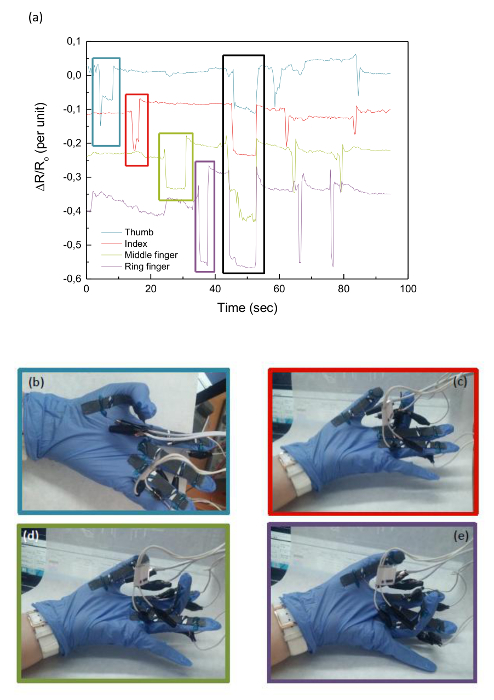

- Attach glass fabric bands to each of the fingers of a nitrile glove with hot melt adhesive on the internal surface as indicated in Figure 2.

- Repeat step 5.1.4 but measure the electrical resistance of contacts placed on the same finger.

- Start the sequence of finger bending to monitor and measure the electrical resistance while fingers are bending. The sequence of finger bending in this particular case is: (1) thumb, (2) index, (3) middle finger, (4) ring finger, (5) all the fingers simultaneously and (6) sequence of bending (higher speed): (1), (2), (3), (4), (4), (3), (2) and (1).

- Monitor finger bending.

Figure 2. Location of f-GNP/glass fiber bands on the internal surface of the fingers of a nitrile glove to monitor fingers bending. Once the glass fiber fabric has been coated and dried, bands 10 mm in width are cut and attached on the different fingers of a glove with the aim of monitoring the finger bending and corroborate the viability of the protocol described above. Please click here to view a larger version of this figure.

Representative Results

The protocol to obtain two different materials has been described in the procedure. The difference is in the way the nanoreinforcement is incorporated in the composite material to achieve an electrical network that could be used to strain monitoring. The first method consists of the coating of a glass fiber fabric with f-GNP sizing that can be used as a smart fabric (named f-GNP/glass fiber) or as reinforcement of polymer matrix multiscale composite materials (named f-GNP/glass fiber composite material). The other method is the nanoreinforcement of the epoxy matrix of composite materials with f-GNPs (named f-GNP/epoxy composite material) using glass fiber as a continuous reinforcement. The infusion of the resin was carried out by using VARIM because it is one of the most common methods used in the industry, but other methods could be used. An alternative manufacturing method could be resin transfer molding (RTM).

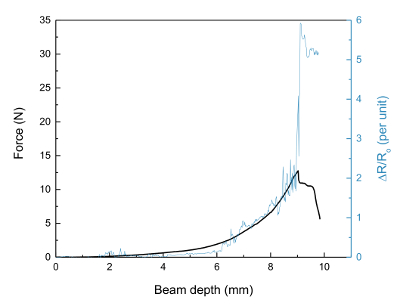

Due to the insulating character of the glass fiber, the incorporation of the f-GNPs following the protocol described above creates an electrical network inside the material that causes an increase of the electrical conductivity up to ~10-3 S/m and can be modified by inducing strain. Figure 3 shows representative results of the variation of normalized electrical resistance caused by strain induced during flexural test (three-point bending) in an f-GNP/glass fiber band. The normalized electrical resistance exponentially grows with the increasing strain due to the mechanism of tunnel resistance. When failure occurs, jumps in the normalized electrical resistance can be observed, which are correlated to a drop of load.

Figure 3. Example of strain monitoring of f-GNP/glass fiber bands under flexural test. The figure represents the variation of the normalized electrical resistance (ΔR/Ro, R: instantaneous electrical resistance and Ro: initial electrical resistance) and force (F) versus beam depth during flexural test. The normalized electrical resistance increases with the strain. This phenomenon occurs because tensile forces cause distancing between the nanoparticles and loss of contact of overlying GNPs. The exponential tendency observed during loading of sample is due to a major contribution of changes induced in tunnel resistance. Tunnel resistance varies exponentially with the distance between nanoparticles when they are at a distance in the order of 10 nm12,21. For that reason when distances between adjacent GNPs increase, the electrical resistance also increases with an exponential tendency. This effect is dominant when the GNP content is close to the percolation threshold23 but its contribution diminishes at higher GNP content24,25. During failure, the electrical behavior changes and jumps are observed in the electrical response. These jumps can be correlated to drops in load provoked by the fiber breakage, which constitutes discontinuities in the electrical network. These discontinuities act as obstacles causing the increment of the electrical resistance of the GNP/glass fiber bands. Please click here to view a larger version of this figure.

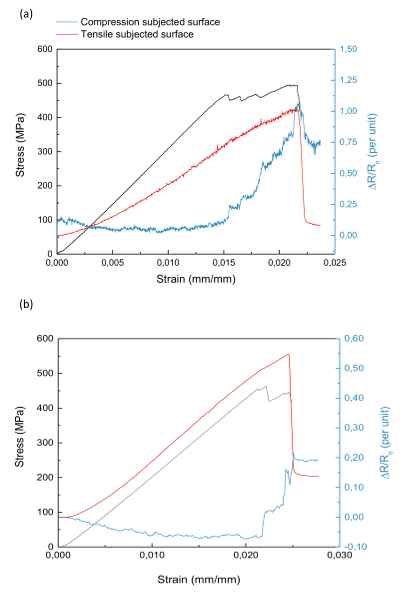

The electrical behavior of the multiscale composite materials, f-GNP/epoxy (Figure 4.a) and f-GNP/glass fiber (Figure 4.b) composite materials, shows some differences with the described above for coated fabrics. When the compression subjected surface is monitored, two regions can be discriminated. At low strain values, the normalized electrical resistance diminishes up to ~0.010 and ~0.015 mm/mm for f-GNP/epoxy and f-GNP/glass fiber composite materials, respectively. In contrast, at strains higher than the mentioned threshold, the normalized electrical resistance increases with an exponential tendency. In the case of monitoring the tensile subjected surfaces, the normalized electrical resistance augments in both of the systems. The sensitivity shown in all the configurations is in the order of 10 to 40 (per unit). At high strain values, the gauge factor was -1.4 and 7.8 (per unit) for the compression subjected surface of f-GNP/epoxy and f-GNP/glass fiber composite materials and on the order of 17 and 41 (per unit) for the tensile subjected surface of f-GNP/epoxy and f-GNP/glass fiber composite materials, respectively.

Figure 4. Example of strain monitoring of (a) f-GNP/epoxy and (b) f-GNP/glass fiber composite materials under flexural test. The figure represents the variation of the normalized electrical resistance (ΔR/Ro, R: instantaneous electrical resistance and Ro: initial electrical resistance) and stress (σ) versus strain (ε) during flexural test. In this case, the electrical contacts are place on the compression subjected (blue line) and the tensile subjected (red line) obtaining different electrical behavior. Two different graphs are included, which correspond to the two routes proposed in the protocol: (a) f-GNP/epoxy and (b) f-GNP/glass fiber composite materials showing their viability. Please click here to view a larger version of this figure.

As an example of the application of f-GNP coated glass fiber fabrics, Figure 5.a shows the monitoring of finger bending. Each finger and the electrical response of the coupled glass fiber band are distinguished by a different color to make it understandable. The first sequence corresponds to bending of the thumb (Figure 5.b), the index (Figure 5.c), the middle finger (Figure 5.d) and the ring finger (Figure 5.e). The normalized electrical resistance diminishes when the related finger bends and recovers the initial value when the finger recuperates the initial position. The second sequence of movements includes simultaneous bending of the four fingers and the third, a sequence of faster movements showing the instantaneous response and recovery of the normalized electrical resistance. This could be used to remotely monitor the evolution of bone diseases or count footsteps during running and in physical therapy to evaluate the recuperation.

Figure 5. Example of strain monitoring of fingers bending by coupling of f-GNP/glass fiber bands on a nitrile glove. (a) Electrical response of the sensor during 3 sequences of fingers bending and (b–e) first sequence of fingers bending. Following the protocol explained in the present work, monitoring of fingers bending capability was possible. ΔR/Ro, R: instantaneous electrical resistance and Ro: initial electrical resistance. Please click here to view a larger version of this figure.

Discussion

Self-sensor properties of nanoreinforced composite materials are due to the electrical network created by the f-GNPs through the epoxy matrix and along the glass fibers, which is modified when strain is induced. Dispersion of the f-GNPs is then crucial because the electrical behavior of the sensors strongly depends on the microstructure of the material. Here, we present an optimized procedure to achieve a good dispersion of the GNPs into the epoxy matrix and to avoid wrinkling of the nanoparticles, which causes the detriment of the electrical conductivity. The critical steps are the sonication (operating parameters) and calendering processes (roller gap and speed). These steps strongly influence the mechanical26, thermal27 and electrical28 properties of the multiscale composite materials. Usually, dispersion of nanoreinforcement is carried out into solvent that needs to be evaporated before the curing of nanocomposites29,30. In the process proposed in this work, the use of solvents is avoided making it more environmentally friendly. Another step of the protocol, which also strongly influences the microstructure of composite materials and, therefore, the electrical behavior of the sensors, is the manufacturing procedure for multiscale composite materials. During manufacturing of these materials, even if good dispersion of the nanoparticles into the epoxy matrix is initially achieved, f-GNP distribution can be strongly affected by filtering phenomena. Additionally, degassing of the epoxy matrix is essential in order to maintain mechanical properties of the multiscale composite materials, which becomes more difficult when the matrix is filled with the GNPs because of a major viscosity.

Electrical contact placement needs to be carried out carefully in order to assure that the electrical contact resistance is as low as possible. For this, it is important to ensure that surfaces are completely cleaned before applying the silver paint to fix the copper electrodes. Furthermore, before applying the hot melt adhesive, the silver paint needs to dry. If not, the solvent evaporates and provokes the appearance of bubbles, increasing the electrical contact resistance. One of the advantages of positioning electrical contacts on the surface of the material, in contrast to the electrodes located inside the sample31, is that it is non-intrusive and is not a detriment to any mechanical properties. During monitoring tests, the electrical contacts can detach from the surface of samples. Consequently, proper fixing is essential to ensure that the electrical signal that is going to be registered corresponds only to the intrinsic electrical response of the material.

The protocol described above can be applied or modified with different nanofillers such as carbon nanotubes or other conductive nanoparticles that also lead to electrically conductive composites with self-sensing properties32,33. The monitoring protocol can be extrapolated to other test configurations for damage detection and quantification. One limitation of the system used for the electrical contacts is that their location on sample surfaces restricts the volume of material where the electrical resistance is analyzed. By designing another system involving volumetric measurements, internal damage could be detected and quantified but in this case, mechanical properties could be compromised. The protocol could be useful in biomechanical applications to remotely monitor the evolution of bone diseases or count footsteps during running or in physical therapy to evaluate the recuperation process.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors would like to acknowledge the Ministerio de Economía y Competitividad of Spain Government (Project MAT2013-46695-C3-1-R) and Comunidad de Madrid Government (P2013/MIT-2862).

Materials

| Graphene Nanoplatelets | XGScience | M25 | NA |

| Epoxy resin | Huntsman | Araldite LY556 | NA |

| XB3473 | NA | ||

| Probe sonication | Hielscher | UP400S | NA |

| Three roll mill | Exakt | Exakt 80E (Exakt GmbH) | NA |

| Glass fiber fabric | Hexcel | HexForce ® 01031 1000 TF970 E UD 4H | NA |

| Hot plate press | Fontijne | Fontijne LabEcon300 | NA |

| Sizing | Nanocyl | SizicylTM | NA |

| Multimeter | Alava Ingenieros | Agilent 34410A | NA |

| Strain Gauges | Vishay | Micro-Measurement (MM®) CEA-06-187UW-120 | NA |

| Mechanical tests machine | Zwick | Zwick/Roell 100 kN | NA |

| Conductive silver paint | Monocomp | 16062 – PELCO® Conductive Silver Paint | NA |

References

- Farrar, C. R., Worden, K. An introduction to structural health monitoring. Philos Trans Math Phys Eng Sci. 365, 303-315 (2007).

- Lorenzo, E. D., et al. Structural Health Monitoring challenges on the 10-MW offshore wind turbine model. J Phys Conf Ser. 628, 012081 (2015).

- Braga, D. F. O. O., et al. Advanced design for lightweight structures: Review and prospects. Prog Aerosp Sci. 69, 29-39 (2014).

- Garcìa Márquez, F. P., Tobias, A. M., PinarPérez, J. M., Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew Energy. 46, 169-178 (2012).

- Chung, D. D. L. Self-monitoring structural materials. Mater Sci Eng R Reports. 22, 57-78 (1998).

- Kandare, E., et al. Improving the through-thickness thermal and electrical conductivity of carbon fibre/epoxy laminates by exploiting synergy between graphene and silver nano-inclusions. Compos Part A Appl Sci Manuf. 69, 72-82 (2015).

- Amjadi, M., Pichitpajongkit, A., Lee, S., Ryu, S., Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano. 8, 5154-5163 (2014).

- Alamusi, H. N., Fukunaga, H., Atobe, S., Liu, Y., Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors. 11, 10691-10723 (2014).

- Njuguna, M. K. K., Yan, C., Hu, N., Bell, J. M. M., Yarlagadda, P. K. D. V. Sandwiched carbon nanotube film as strain sensor. Compos Part B Eng. 43, 2711-2717 (2012).

- Liu, Y., Rajadas, A., Chattopadhyay, A. A biomimetic structural health monitoring approach using carbon nanotubes. JOM. 64, 802-807 (2012).

- Eswaraiah, V., Balasubramaniam, K., Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J Mater Chem. 21, 12626-12628 (2011).

- Chiacchiarelli, L. M., et al. The role of irreversible and reversible phenomena in the piezoresistive behavior of graphene epoxy nanocomposites applied to structural health monitoring. Compos Sci Technol. 80, 73-79 (2013).

- Le, J., Du, H., Dai, S. Use of 2D Graphene Nanoplatelets (GNP) in cement composites for structural health evaluation. Compos Part B. 67, 555-563 (2014).

- Ren, X., Burton, J., Seidel, G. D., Lafdi, K. Computational multiscale modeling and characterization of piezoresistivity in fuzzy fiber reinforced polymer composites. Int J Solids Struct. 54, 121-134 (2015).

- Park, M., Park, J., Jeong, U. Design of conductive composite elastomers for stretchable electronics. Nano Today. 9, 244-260 (2014).

- Kim, Y. J., et al. Preparation of piezoresistive nano smart hybrid material based on graphene. Curr Appl Phys. 11, S350-S352 (2011).

- Sadeghi, M. M., Pettes, M. T., Shi, L. Thermal transport in graphene. Solid State Commun. 152, 1321-1330 (2012).

- Potts, J. R., Dreyer, D. R., Bielawski, C. W., Ruoff, R. S. Graphene-based polymer nanocomposites. Polymer. 52, 5-25 (2011).

- Zaman, I., et al. A facile approach to chemically modified graphene and its polymer nanocomposites. Adv Funct Mater. 22, 2735-2743 (2012).

- Moriche, R., et al. Morphological changes on graphene nanoplatelets induced during dispersion into an epoxy resin by different methods. Compos Part B Eng. 72, 199-205 (2015).

- ASTM International. . ASTM D790-15e2, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. , D790 (2015).

- Gong, S., Zhu, Z. H., Meguid, S. A. Carbon nanotube agglomeration effect on piezoresistivity of polymer nanocomposites. Polymer. 55, 5488-5499 (2014).

- Zhao, J., et al. Ultra-sensitive strain sensors based on piezoresistive nanographene films. Appl Phys Lett. 101, 063112 (2012).

- Galpaya, D., et al. Recent advances in fabrication and characterization of graphene-polymer nanocomposites. Graphene. 1, 30-49 (2012).

- Kanoun, O., et al. Flexible Carbon Nanotube Films for High Performance Strain Sensors. Sensors. 14, 10042-10071 (2014).

- Zaman, I., et al. Epoxy/graphene platelets nanocomposites with two leves of interface strength. Polymer. 52, 1603-1611 (2011).

- Chu, K., Li, W. S., Dong, H. Role of graphene waviness on the thermal conductivity of graphene composites. Appl Phys A. 111, 221-225 (2013).

- Monti, M., et al. Morphology and electrical properties of graphene-epoxy nanocomposites obtained by different solvent assisted processing methods. Compos Part A. 46, 166-172 (2013).

- Moazzami Gudarzi, M., Sharif, F. Enhancement of dispersion and bonding of graphene-polymer through wet transfer of functionalized graphene oxide. Express Polym Lett. 6, 1017-1031 (2013).

- Fan, H., et al. Fabrication, mechanical properties and biocompatibility of graphene-reinforced chitosan composites. Biomacromolecules. 11, 2345-2351 (2010).

- Teomete, E. Transverse strain sensitivity of steel fiber reinforced cement composites tested by compression and split tensile tests. Constr Build Mater. 55, 136-145 (2014).

- Nauman, S., Cristian, I., Koncar, V. Simultaneous Application of Fibrous Piezoresistive Sensors. Sensors. 11, 9478-9498 (2011).

- Han, B., Ding, S., Yu, X. Intrinsic self-sensing concrete and structures A review. Measurement. 59, 110-128 (2015).