5.11:

Sieve Analysis and Grading Curves

このコンテンツを視聴するには、JoVE 購読が必要です。 サインイン又は無料トライアルを申し込む。

JoVE Core

Civil Engineering

Sieve Analysis and Grading Curves

7 Views

•

01:19 min

•

November 07, 2024

Sieve analysis is a method used to determine the particle size distribution of aggregate materials. This process involves the following steps:

- The required quantity of dried sample of aggregate is weighed.

- The weighed aggregates are sieved through a set of sieves with square openings arranged in descending order of aperture size, with the largest mesh on top (Column 1 of Table 1).

- The stack of sieves is shaken or vibrated to facilitate the sorting of particles by size.

- After sieving for a specific period, the material retained on each sieve is weighed (Column 2 of Table 1).

- The weight of particles retained on each sieve is expressed as a percentage of the total sample mass (Column 3 of Table 1).

- The cumulative percentage passing each sieve is calculated to the nearest one percent from the finest sieve moving upwards (Column 4 of Table 1).

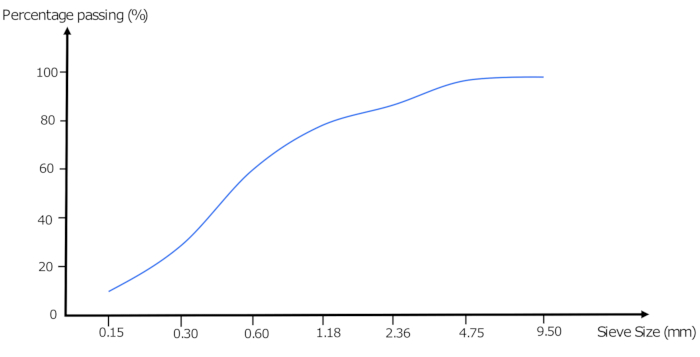

- The grading curve is plotted on a graph (Figure 1) where the ordinate values represent the percentage passing (Column 4 of Table 1), and the abscissa values show the sieve apertures (Column 1 of Table 1), set to a logarithmic scale.

Table 1: Data for sieve analysis on sand

| Column 1 | Column 2 | Column 3 | Column 4 |

| ASTM Sieve (Sieve size) | Weight retained on each sieve (g) | Percentage weight retained on each sieve (%) | Cumulative Percentage passing each sieve (%) |

| ⅜ inch (9.5 mm) | 0 | 0 | 98+2 = 100 |

| No. 4 (4.75 mm) | 10 | 2 | 88+10 = 98 |

| No. 8 (2.36mm) | 50 | 10 | 79+9 = 88 |

| No. 16 (1.18 mm) | 45 | 9 | 61+18 = 79 |

| No. 30 (600 µ) | 90 | 18 | 29+32 = 61 |

| No. 50 (300 µ) | 160 | 32 | 10+19 = 29 |

| No. 100 (150 µ) | 95 | 19 | 10 |

| Bottom pan | 50 | 10 | |

| Total weight of aggregate = 500 g | |||

Grading curves visually simplifies the distribution of particle sizes and is essential for ensuring that aggregates meet the required grading specifications for construction projects.