A Novel Biaxial Testing Apparatus for the Determination of Forming Limit under Hot Stamping Conditions

Summary

This protocol proposes a novel biaxial testing system used on a resistance heating uniaxial tensile test machine in order to determine the forming limit diagram (FLD) of sheet metals under hot stamping conditions.

Abstract

The hot stamping and cold die quenching process is increasingly used to form complex shaped structural components of sheet metals. Conventional experimental approaches, such as out-of-plane and in-plane tests, are not applicable to the determination of forming limits when heating and rapid cooling processes are introduced prior to forming for tests conducted under hot stamping conditions. A novel in-plane biaxial testing system was designed and used for the determination of forming limits of sheet metals at various strain paths, temperatures, and strain rates after heating and cooling processes in a resistance heating uniaxial testing machine. The core part of the biaxial testing system is a biaxial apparatus, which transfers a uniaxial force provided by the uniaxial testing machine to a biaxial force. One type of cruciform specimen was designed and verified for the formability test of aluminum alloy 6082 using the proposed biaxial testing system. The digital image correlation (DIC) system with a high-speed camera was used for taking strain measurements of a specimen during a deformation. The aim of proposing this biaxial testing system is to enable the forming limits of an alloy to be determined at various temperatures and strain rates under hot stamping conditions.

Introduction

The automotive industry is facing a huge global challenge of reducing fuel consumption and minimizing environmental pollution from vehicle emissions. Weight reduction is beneficial to improving the performance of automobiles and can directly reduce energy consumption1. Due to the low formability of sheet metals at room temperature, hot stamping and cold die quenching processes (referred to as hot stamping)2 are used to improve the formability of alloys and thus to obtain complex shaped components in automotive applications.

A forming limit diagram (FLD) is a useful tool to evaluate the formability of an alloy3. Out-of-plane tests, such as the Nakazima test4,5, and in-plane tests, such as the Marciniak test6,7,8, are conventional experimental methods to obtain the FLDs of sheet metals under various conditions9,10,11. A servo-hydraulic biaxial testing machine has also been used to investigate the formability of alloys at room temperature12,13.

However, none of the methods above are applicable to formability tests under hot stamping conditions, since a cooling process prior to forming is required along with control of the heating and cooling rates. The deformation temperature and strain rate are difficult to obtain accurately. Therefore, a novel formability testing system is proposed in this study to experimentally determine the forming limits of sheet metals under hot stamping conditions.

Protocol

1. Preparation of Specimens

- Machine flat dog-bone and cruciform specimens from commercial material aluminum alloy 6082 (AA6082) using a laser cutter and a computer numerical control (CNC) milling machine (for formability tests at different strain paths including uniaxial, plane strain, and equi-biaxial straining states).

- Measure the thickness of each cruciform specimen and each dog-bone specimen with a vernier caliper three times in the central gauge region and calculate the average values. Ensure that the thickness of the gauge section in a cruciform specimen is 0.7 ± 0.05 mm and that the thickness of the uniaxial specimen is 1.5 ± 0.1 mm.

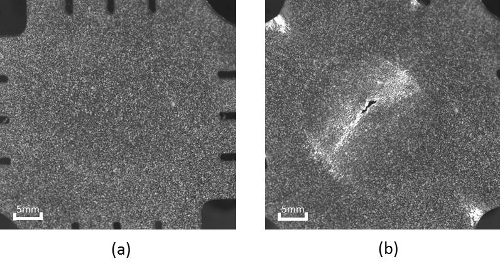

- Spray-paint the entire top surface of a cruciform specimen by using a flame-resistant, black spray paint (capable of withstanding temperatures up to 1,093 °C). Wait until the paint dries and then spray flame-resistant, white paint dots from arm's length to create a stochastic spraying pattern to be recognized by the DIC system (see the example in Figure 1).

- Weld a pair of thermocouples to the center of the back surface (opposite to the painted surface) of the specimen. Connect the other end of the thermocouple to the feedback temperature control system of the uniaxial testing machine to monitor and control the temperature change history.

2. Assembly of the Biaxial Testing Apparatus

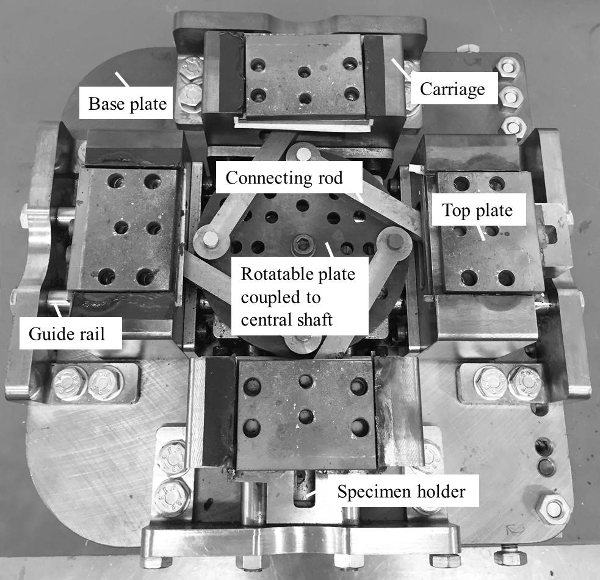

- Assemble all parts of the biaxial testing apparatus, including a base plate, a central shaft, input and output rotatable plates, carriages, a clamp, guide rails, and rigid connecting rods (the assembled apparatus is shown in Figure 2).

- Using a connecting rod, couple the input rotatable plate directly to the movable jaw of a resistance heating uniaxial tensile test machine, which provides the uniaxial tensile force. Couple the input rotatable plate to the central drive shaft and couple this central drive shaft to the output rotatable plate.

- Ensure that the rotation of the input rotatable plate around the axis of rotation rotates the drive shaft, thereby rotating the output rotatable plate to which it is coupled around the axis of rotation.

- At one end, couple each of the rigid connecting rods to one of the connection points on the output rotatable plate. Couple the other end to one of the carriages.

NOTE: This will cause the carriages with specimen holders to slide back and forth along the guide rails with low friction, which can apply a biaxial force to the cruciform specimen. - Using screw bolts, clamp each arm of the cruciform specimen to a carriage with a specimen holder and a top plate.

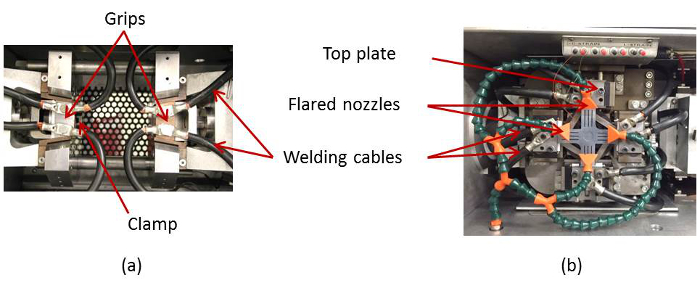

- Set up grips in the chamber of the uniaxial tensile test machine, as shown in Figure 3 (a). Attach four welding cables to each pair of grips, which are made of stainless steel and copper, respectively, and thus connect the welding cables to the electrical power supply.

NOTE: The conductor area of the welding cables is 50 mm2 and the current rating is 345 A.- Put the grips and the clamp of the biaxial testing apparatus into the two jaws of the uniaxial tensile test machine and tighten them inside (Figure 3 (a)).

- Set up the biaxial testing apparatus in the chamber of the uniaxial tensile test machine, as shown in Figure 3 (b).

- Use two frames and screw bolts on the top and the bottom sides of the base plate to fix the apparatus in the chamber of the uniaxial tensile test machine.

- Put the specimen into the specimen holder on top of the biaxial testing apparatus.

- Connect each terminal of the welding cables to each clamping region of the specimen.

3. Setup of the Heating and Quenching System

- Tightly connect each clamping region of the specimen to the stainless steel top plate, which serves as the electrode for resistance heating.

- Tighten the welding cables with crimp ring terminals to the top plate of each clamping region.

- Connect flared nozzles with hoses to the high flow quench system with regulated air supply at 8,000 kg/m2 pressure for cooling.

- Use four nozzles to blow air from the arms of the specimen to the central region of the specimen.

NOTE: The nozzles are not directed onto the gauge section for cooling to avoid blocking the central zone from the camera's view.

4. Setup of the DIC System

- Connect the high-speed camera of the DIC system with a micro lens to a computer. Adjust the frame rates of the camera to 25 fps, 50 fps, and 500 fps from the menu of frame rates (for the tests at the stretching strain rates of 0.01/s, 0.1/s and 1/s, respectively). Set the resolutions of all images to 1,280×1,024 pixels.

NOTE: The frame rates depend on the number of data points to be collected; at least 200 data points can be collected using the above settings. - Use an additional spotlight with a power of 300 W for tests at high strain rates. Point the spotlight directly at the chamber of the uniaxial tensile test machine.

- Adjust the camera lens so that it is parallel to the top surface of the specimen in the chamber and focus the camera on the gauge section.

5. Experimental Program

- Run the resistance heating uniaxial tensile test machine by clicking the triangular run button in the control software.

NOTE: Electricity runs through the AA6082 material and heats it to the solution heat treatment temperature of 535 °C14 at a heating rate of 30 °C/s. The material is soaked at 535 °C for 1 min, which is sufficient for the full resolution of precipitates. Air blowing from the quench system is used to quench the material at a cooling rate of 100 °C/s15 to one of 3 designated elevated temperatures in the range of 370-510 °C. - Stretch the specimen with the biaxial testing apparatus at a constant strain rate in the range of 0.01-1/s and record the deformation history by manually pressing the trigger button connected to the high-speed camera.

NOTE: The input displacement from the uniaxial testing machine to the biaxial testing apparatus was controlled by the built-in software of the uniaxial testing machine. - Perform the tests at different strain paths consisting of uniaxial, plane strain, and biaxial straining states3 by adjusting the configuration of the biaxial testing apparatus.

- Disconnect two opposed connecting rods for uniaxial tests. Clamp a dog-bone specimen on the biaxial testing apparatus and connect it to welding cables, as in steps 3.1-3.4. Repeat steps 5.1-5.2.

- Fix two opposed carriages to the base plate with screw bolts to restrict the deformation on the corresponding direction for testing under plane strain state. Clamp a cruciform specimen on the biaxial testing apparatus and connect it to welding cables, as in steps 3.1-3.4. Repeat steps 5.1-5.2.

- Repeat steps 5.3.1-5.3.2 for each test condition three times, using new dog-bone and cruciform specimens.

6. Data Processing

- Import all images recorded by the high-speed camera into the post-processing software and follow standard steps for data analysis according to the software manual.

- Use the ISO standard3 to determine the forming limits by clicking the FLC Mode button in the software.

NOTE: This method has already been integrated into the image correlation processing software. - Mark each result of the forming limits at various temperatures, strain rates, and strain paths in a diagram.

- Plot the forming limit curves at all test conditions to obtain an FLD of an alloy under hot stamping conditions.

Representative Results

Since FLDs are highly strain path-dependent, the linearity of the strain path for each test condition was verified by analyzing the DIC results; the strain paths are proportional throughout deformation for each test condition. The range of the minor-to-major strain ratio is approximately -0.37 (uniaxial condition) to 0.26 (near biaxial condition). By processing data for different AA6082 conditions, forming limit data for different strain paths were determined and hence, the FLDs for AA6082 at hot stamping conditions were obtained through curve fitting. In Figure 3, forming limit data were obtained at various temperatures, strain rates, and strain paths after the heating and cooling processes. The fitted dashed lines indicate the formability of this alloy, AA6082. A forming limit curve identifies the boundary between uniform deformation and the onset of plastic instability or diffuse necking, which lead to failure. The region above the curve represents potential failure, and the region below the curve is regarded as a safety region, where uniform deformation occurs at the corresponding testing conditions. A higher FLC indicates that the material has better formability if the shape remains the same.

Formability tests using the novel in-plane biaxial tensile testing system were conducted at the designated deformation temperatures and strain rates after the heating and cooling processes. It was found that, when the strain rate increases from the designated strain rate of 0.01/s to 1/s, the forming limit of AA6082 increases. The forming limit has a larger increase, from 0.1/s to 1/s, than from 0.01/s to 1/s, as shown in Figure 4 (a).

In Figure 4 (b), there is a monotonic increase in the forming limit from 370 °C to 510 °C. This indicates that high formability of AA6082 can be obtained at a higher temperature under hot stamping conditions. The three forming limit curves are quite close to each other on the left side of the FLD, which means that the sensitivity of temperature dependence is larger for tension-tension biaxial strain paths than for tension-compression strain paths.

Figure 1: An example of a stochastic pattern in a cruciform specimen before biaxial stretching (a) and after biaxial stretching (b). The pattern with white dots on a black background is captured by the high-speed camera during tests. The size and density of the speckles within a pattern are subjected to the standard requirements of DIC analysis15. Please click here to view a larger version of this figure.

Figure 2: The assembled biaxial testing apparatus. The apparatus includes a base plate, a central shaft, rotatable plates, carriages, guide rails, and connecting rods. It is mounted in the chamber of the resistance heating uniaxial testing machine. Key components have been marked in the figure. Please click here to view a larger version of this figure.

Figure 3: Setup of grips and the biaxial testing apparatus in the chamber of the uniaxial testing machine. (a) The grips and the clamp. (b) The biaxial testing apparatus and nozzles for air cooling. Please click here to view a larger version of this figure.

Figure 4: FLDs of AA6082 at (a) different strain rates and (b) different temperatures under hot stamping conditions. The symbols are the results of the forming limits under different conditions. The dashed lines were obtained through the polynomial fitting algorithm. Please click here to view a larger version of this figure.

Discussion

Conventional formability test methods used to determine forming limits are usually applicable only at room temperature. The presented technique can be used to evaluate the formability of metals for hot sheet stamping applications by introducing a novel biaxial testing apparatus to a resistance heating uniaxial testing machine. This cannot be performed using conventional methods for hot stamping applications. The setup of heating and cooling systems and the DIC system is critical to controlling the uniformity of temperature distribution in a specimen and thus to recording the deformation history of stretching specimens.

In this technique, the heating and cooling rates can be precisely controlled by the uniaxial tensile test machine for complex forming process applications. The biaxial mechanism has a relatively simple configuration, which reduces the cost and complexity of biaxial tensile testing compared to traditional biaxial testing mechanisms. However, temperature fields made by resistance heating are affected by specimen design in this testing system, and temperature gradients on a specimen cannot be avoided. No existing standard specimen design is available for this type of biaxial testing.

In summary, this is the first time that an FLD of alloys under hot stamping conditions was obtained. High forming speeds and high temperatures within the designated ranges are beneficial for enhancing the forming limits of AA6082 under hot stamping conditions. This novel technique can be used to determine the forming limits of sheet metals under complex testing conditions. The obtained experimental results can be used to develop a material model that predicts the thermo-mechanical behavior and the formability of an alloy. The mechanism of the apparatus can be modified to conduct formability tests subjected to non-linear strain paths in the future.

Declarações

The authors have nothing to disclose.

Acknowledgements

This research was supported by the European Union’s Seventh Framework Programme (FP7/2007-2013) under grant agreement No. 604240, project title “An industrial system enabling the use of a patented, lab-proven materials processing technology for Low Cost forming of Lightweight structures for transportation industries (LoCoLite).”

Materials

| Aluminium Alloy | Smiths Metal | 6082 | Specimens machining |

| Laser cutter | LVD Ltd | HELIUS 25/13 | Laser cutting specimens |

| CNC machine | HAAS Automation | TM-2CE | Machine specimens by milling |

| Vernier caliper | Mitutoyo | 575-481 | Thickness measurement |

| Resistance heating uniaxial testing machine | Dynamic System Inc | Gleeble 3800 | Thermo-mechanical materials simulator |

| High flow quench system | Dynamic System Inc | 38510 | For air cooling |

| Thermocouples | Dynamic System Inc | K type | |

| Nozzles | Indexa | Nozzle flared 1/4 inch bore | |

| Welding cables | LAPP Group | H01N2-D | |

| High-speed camera | Photron | UX50 | For DIC testing |

| Camera lens | Nikon | Micro 200mm | |

| Lamp | Liliput | 150ce | 300W |

| Laptop | HP | Campaq 2530p | For images recording |

| Biaxial testing apparatus | Manufactured independently | All parts were designed and machinced by authors for biaxial testing | |

| Steel | West Yorkshire Steel | H13 | Mateials of the biaxial testing apparatus |

| Image correlation processing software | GOM | ARAMIS | Non-contact measuring system and data post-pocessing |

Referências

- Karbasian, H., Tekkaya, A. E. A review on hot stamping. J. of Mater. Process. Tech. 210 (15), 2103-2118 (2010).

- Miller, W. S., et al. Recent development in aluminium alloys for the automotive industry. Mater. Sci. and Eng. 280 (1), 37-49 (2000).

- Shao, Z., Li, N., Lin, J., Dean, T. A. Development of a New Biaxial Testing System for Generating Forming Limit Diagrams for Sheet Metals Under Hot Stamping Conditions. Exp. Mech. 56 (9), 1-12 (2016).

- Ayres, R. A., Wenner, M. L. Strain and strain-rate hardening effects in punch stretching of 5182-0 aluminum at elevated temperatures. Metall. Trans. A. 10 (1), 41-46 (1979).

- Shao, Z., et al. Experimental investigation of forming limit curves and deformation features in warm forming of an aluminium alloy. P. I. Mech. Eng. B-J. Eng. , (2016).

- Marciniak, Z., Kuczynski, K. Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 9 (9), 609-620 (1967).

- Li, D., Ghosh, A. K., et al. Biaxial warm forming behavior of aluminum sheet alloys. J. of Mater. Process. Tech. 145 (3), 281-293 (2004).

- Palumbo, G., Sorgente, D., Tricarico, L. The design of a formability test in warm conditions for an AZ31 magnesium alloy avoiding friction and strain rate effects. Int. J. Mach. Tool. Manu. 48 (14), 1535-1545 (2008).

- Raghavan, K. S. A simple technique to generate in-plane forming limit curves and selected applications. Metall. Mater. Trans. A. 26 (8), 2075-2084 (1995).

- Ragab, A. R., Baudelet, B. Forming limit curves: out-of-plane and in-plane stretching. J. Mech. Work. Technol. 6 (4), 267-276 (1982).

- Fan, X. -. b., He, Z. -. b., Zhou, W. -. x., Yuan, S. -. j. Formability and strengthening mechanism of solution treated Al-Mg-Si alloy sheet under hot stamping conditions. J. of Mater. Process. Tech. 228, 179-185 (2016).

- Zidane, I., Guines, D., Léotoing, L., Ragneau, E. Development of an in-plane biaxial test for forming limit curve (FLC) characterization of metallic sheets. Meas. Sci. Technol. 21 (5), 055701 (2010).

- Hannon, A., Tiernan, P. A review of planar biaxial tensile test systems for sheet metal. J. of Mater. Process. Tech. 198 (1-3), 1-13 (2008).

- Garrett, R., Lin, J., Dean, T. An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: experimentation and modelling. Int. J. Plasticity. 21 (8), 1640-1657 (2005).

- Milkereit, B., Wanderka, N., Schick, C., Kessler, O. Continuous cooling precipitation diagrams of Al-Mg-Si alloys. Mater. Sci. Eng. A. 550, 87-96 (2012).

- Crammond, G., Boyd, S. W., Dulieu-Barton, J. M. Speckle pattern quality assessment for digital image correlation. Opt. Laser. Eng. 51 (12), 1368-1378 (2013).