Low-cost Custom Fabrication and Mode-locked Operation of an All-normal-dispersion Femtosecond Fiber Laser for Multiphoton Microscopy

概要

A method is presented to build a custom low-cost, mode-locked femtosecond fiber laser for potential applications in multiphoton microscopy, endoscopy, and photomedicine. This laser is built using commercially available parts and basic splicing techniques.

Abstract

A protocol is presented to build a custom low-cost yet high-performance femtosecond (fs) fiber laser. This all-normal-dispersion (ANDi) ytterbium-doped fiber laser is built completely using commercially available parts, including $8,000 in fiber optic and pump laser components, plus $4,800 in standard optical components and extra-cavity accessories. Researchers new to fiber optic device fabrication may also consider investing in basic fiber splicing and laser pulse characterization equipment (~$63,000). Important for optimal laser operation, methods to verify true versus apparent (partial or noise-like) mode-locked performance are presented. This system achieves 70 fs pulse duration with a center wavelength of approximately 1,070 nm and a pulse repetition rate of 31 MHz. This fiber laser exhibits the peak performance that may be obtained for an easily assembled fiber laser system, which makes this design ideal for research laboratories aiming to develop compact and portable fs laser technologies that enable new implementations of clinical multiphoton microscopy and fs surgery.

Introduction

Solid state femtosecond (fs) pulsed lasers are widely used for microscopy and biological research. One typical example is the usage of multiphoton excitation (MPE) fluorescence microscopy, where high peak power and low average power are desired to facilitate the MPE process while minimizing photodamage mechanisms. Many high-performance solid-state lasers are commercially available, and when combined with an optical parametric oscillator (OPO), the laser wavelength can be tuned over a wide range1. For example, commercial oscillator-OPO systems generate <120 fs pulse durations (typically with an 80 MHz pulse repetition rate) and >1 W average power from 680 to 1,300 nm. However, the cost of these commercial tunable fs laser systems is significant (>$200,000), and solid-state systems generally require water cooling and are not portable for clinical applications.

Ultrashort pulsed fiber laser technology has matured in the past few years. The cost of a commercial fs pulsed fiber laser is typically significantly lower than solid-state lasers, albeit without the capability of broad wavelength tuning afforded by the solid-state systems mentioned above. Note that fiber lasers can be paired with OPOs when desired (i.e., hybrid fiber-solid-state systems). The large surface-to-volume ratio of fiber laser systems enables efficient air cooling2. Hence, fiber lasers are more portable than solid-state systems due to their relatively small size and simplified cooling system. Further, fusion splicing of the fiber components reduces system complexity and mechanical drift in contrast to the free-space alignment of the optical components making up solid-state devices. All of these features make fiber lasers ideal for clinical applications. In fact, all-fiber lasers have been developed for low-maintenance operation3,4,5, and all-polarization-maintaining (PM)-fiber lasers are stable to environmental factors including changes in temperature and humidity as well as mechanical vibrations2,6,7,8.

Here, a method is presented to build a cost-efficient fs pulsed ANDi fiber laser with commercially available parts and standard fiber splicing techniques. Methods to characterize pulse repetition rate, duration, and coherence (full mode-lock) are also presented. The resulting fiber laser generates mode-locked pulses that can be compressed to 70 fs with a repetition rate of 31 MHz and a wavelength centered at 1,060 to 1,070 nm. The maximum power output from the laser cavity is approximately 1 W. The pulse physics of ANDi fiber lasers elegantly utilizes nonlinear polarization evolution intrinsic to optical fiber as a key component of the saturable absorber2,3,9,10,11. However, this means that the ANDi design is not easily implemented using PM fiber (although an all-PM fiber implementation of ANDi mode-locking has been reported, albeit with low power and ps pulse duration12). Thus, environmental stability requires significant engineering. Next generation fiber laser designs, such as the Mamyshev oscillator, have the potential to offer complete environmental stability as all-PM-fiber devices capable of an order-of-magnitude increase in intracavity pulse energy as well as offering significant decreases in pulse duration to enable applications that rely on broad pulse spectra13,14. Custom fabrication of these innovative new fs fiber laser designs requires know-how and fiber splicing experience.

Protocol

1. Splice single mode fibers (SMF)

NOTE: Section 1 consists of general steps to splice SMFs. This is a non-essential, but recommended, step for practicing fiber splices using inexpensive fiber. This step ensures proper performance of the splicing equipment before using more valuable fiber optic materials.

- Cleave the first fiber.

- Strip approximately 30 mm of the fiber with a fiber stripping tool. For fragile fibers (e.g., double clad fibers), a razor blade can be used to carefully peel off the buffer.

- Use lint-free tissue with ethanol or isopropanol to clean the stripped fiber. A buzzing sound when wiping the fiber indicates that the fiber is sufficiently clean.

- Place the fiber holder on the fiber cleaver. Make sure the blade, the fiber clamp of the cleaver, and the fiber holder are all clean. Cotton swabs with alcohol can be used to clean these parts of the cleaver.

- Carefully load the fiber into the fiber holder. Leave approximately 25 mm of stripped, clean fiber at the free end for the cleaver to clamp.

- Gently close the fiber clamp on the cleaver. To avoid extra tension applied to the fiber, reopen, and close the clamp so that the tension is released.

- Press the "cut" button and the cleaver will automatically cleave the fiber.

NOTE: To ensure that the fiber remains clean, nothing should touch the fiber tip after cleaving. - Transfer the fiber holder to the fusion splicer. Use tweezers to move the piece cut off from the fiber to a sharps disposal container.

CAUTION: Hard tweezers and sharp tweezer tips can break the fiber. An appropriate tweezer for handling fiber optics should have plastic, rounded tips.

- Cleave the second fiber.

- Repeat step 1.1 on the second fiber with the other fiber holder. The two fibers to be spliced should be cleaved with the cleaved ends held opposing each other by the fiber holders within the fiber splicer.

- Close the cover of the splicer.

- Fusion splice the fibers.

- Set up the parameters on the fusion splicer, including the core diameter, mode-field diameter (MFD), and cladding diameter. Set the alignment method to Cladding.

- Press the start button, and the splicer will align automatically.

NOTE: It is possible to get error messages regarding a poor cleave shape or large cleave angle. This is usually due to a poor cleave or contamination of the fiber after the cleave. If this occurs, repeat the fiber cleaving procedure. - Press the start button at each stop to confirm the quality of the splice. The splice will be done automatically.

- Check the quality of the splice via the quality control checks performed by the splicer as well as by using the camera view of the splice region. A good splice has a uniform cladding boundary and uniform brightness along the fiber such that no splice juncture is visible.

NOTE: Fiber splicers often include optics to inspect the splice and to estimate the power loss based on the measured geometry, shape, and light refraction through the fiber using a source perpendicular to the fiber to view, image, and analyze the splice joint. Of course, this is only an estimate, but it is sufficient in most cases. For identical fibers, the splicer will estimate this loss as ~0 dB (i.e., no detectable loss). From previous results with the dissimilar fiber splices described below, the splicer estimates of the power losses range from 0.07 dB (splice points B and C, Figure 1) to 0.3 dB (splice point D). These estimates most likely overestimate the loss due to mismatched geometry and refraction of the dissimilar fiber optics, which falsely appear as defect objects. - Open the splicer cover, then open one of the fiber holders. The other fiber holder should not be opened until the spliced fiber is removed from the splicer.

- As an option, a fiber sleeve may be added to protect the splice. The heater on the splicer may be used to mold the sleeve onto the fiber. Alternatively, a hot air gun may be used.

NOTE: If the two fibers are very long or attached to other components, the sleeve should be put on one of the fibers before cleaving, and then it can be moved to the splicing point. The fiber sleeve acts like a heat shrink tube in electronic circuits. It can be used to protect the splicing point from a bending or pulling force. A fiber recoater may be used instead to recoat the splice point for maximal protection of the splice point to mechanical damage, albeit at a significant additional expense because this equipment must be purchased if it is not readily available.

2. Assemble the fiber parts

- Splice the pump output fiber <1> with the pump input <2> of the pump signal combiner (see the fiber laser diagram, Figure 1).

- Follow section 1 to cleave and splice the fibers. Use the default setting of the program BASIC I SP, with the exception of the fiber parameters (2-A and 2-B) that need to be input manually. The splicing parameters that need to be entered can be found in Table 1.

- Splice the combiner output <3> to the Yb-doped active fiber.

- Follow step 1.1 to cleave the combiner output fiber <3>.

- Cleave the active fiber <4>.

NOTE: Because the active fiber <4> has an octagonal cladding, it does not fit the V-groove of the fiber cleaver. Therefore, a simple cleave as described in step 1.1 will yield a relatively large cleave angle. Thus, the following steps outline a special protocol to achieve a flat cleave angle using the same equipment.- Follow section 1 to cleave and splice the active fiber <4> and a piece of 6/125 SMF. This SMF is removed later and is not incorporated into the laser. Therefore, it is acceptable if the quality of this cleave angle is poor. It is not important to obtain a flat cleave angle for this step.

- Cut the SMF about 2 cm from the splicing point with a wire cutter.

- Strip the entire length of the SMF, and strip the active fiber for another 0.5 cm. Now the active fiber is capped with 2 cm of bufferless SMF.

- Load the active fiber into the cleaver as in steps 1.1.3-1.1.5. Make sure only the SMF, which has a circular cladding, is clamped by the fiber clamp.

- Follow steps 1.1.6 and 1.1.7 to cleave the active fiber <4>. Since only the SMF is in the V-groove, this cleave will yield a minimal cleave angle.

- Follow step 1.3 to splice the fibers.

- Roughly measure the total power output from the distal end of the active fiber <4>.

- Cut the active fiber <4> at ~3 m from splice point <B>. Longer active fiber can be used for a higher output power, but the repetition rate will be reduced due to the increase in the cavity length.

- Cleave the end <4C> as mentioned in step 1.1.

NOTE: Because the power measurement in the next step is estimated, it is unnecessary to use the method mentioned in step 2.2.2. - Point the fiber towards the power meter and bring the fiber and power meter together without physical contact.

WARNING: Putting the tip of the fiber too close to the power meter will possibly damage the power meter sensor, as the light power is concentrated to a small point on the sensor. To avoid this, use a minimum reliable pump power. - Read the power output from power meter. A large (>80%) efficiency throughput indicates sufficient quality splices at points <A> and <B>.

NOTE: It is normal to have some power loss due to the absorption of the active fiber and due to the inefficiency of the coupling method to the power meter as mentioned in steps 2.3.2 to 2.3.3.

- Splice the active fiber <4> to the input <5> of the collimator <Col1>.

- Follow step 2.2.2 to cleave the active fiber <4> on the end <C> to be spliced to the collimator.

- Cut the input <5> of collimator <Col1> to approximately 40 cm.

NOTE: The length of the passive fiber (<5>) should not be too long (>40 cm), because the amplified pulse will broaden substantially in the time and the spectral domain due to increased self-phase modulation (SPM) and group velocity dispersion (GVD) following passage through the gain fiber (pulse amplification). These effects will increase the difficulty of pulse compression. - Follow steps 1.1 and 1.3 to cleave the collimator input <5> and splice the active and collimator fibers.

NOTE:This splice <C> splice of a double clad fiber to an SMF may appear to be of a lower quality than the prior splices. However, the actual performance depends only on the core alignment because the pulse propagates within the core.

- Splice fiber <6> of the second collimator <Col2> to the signal input fiber <7> of the combiner.

- Follow section 1 to cleave and splice the fibers.

3. Mount the fiber parts to the optical table

- Mount the pump laser to the optical table with screws and any necessary clamps.

- Mount the pump signal combiner to the optical table with clamps. Thermal paste can be used between the combiner and the table, because the optical table works as a heat sink for the combiner.

- Place the fibers on the table. Fibers 1, 2, 3, 5, 6, and 7 can be coiled individually to save space, while the active fiber 4 should be either straight or coiled loosely with a radius of curvature >20 cm. Leave some space to access splice <C> for the next step.

CAUTION: A strong bend in the active fiber may cause the pump signal to escape the inner cladding of the active fiber. This can lead to fatal burn points along the active fiber that will require installing a new active fiber. - Apply the index matching gel to splice <C>. The index matching gel is used to guide the pump light out of the active fiber in order to reduce the generation of heat and thermal damage at the splice point. Note that there is no need to recoat the fiber. It is preferable to leave the fiber bare and coated in index matching gel to minimize the risk of thermal damage.

- Use optomechanical parts to mount and fix the two collimators <Col1> and <Col2> on the optical table. The collimators should face each other with a separation of approximately 35 cm to provide sufficient space for inserting the in-cavity free-space components.

4. Assemble the free-space parts

- Turn on the pump laser. Set the power to 0.5 W (i.e., above the threshold for mode-locking yet a safe power for aligning system components).

WARNING: At this point, the laboratory space must be Class IV laser certified, laser safety goggles must be worn, and the personnel must have received Class IV laser training. - Use an infrared (IR) scope to check the splice point <C>. Apply the index matching gel on any bright spots seen through the IR scope (indicative of potential points of thermal damage) in order to help light escape at these risk points.

- Adjust the position of the two collimators so that they are pointing directly at each other. An IR viewing card can be used to assist centered beam alignment at the collimator entrance apertures.

- Mount a polarizing beam splitter (PBS) 6 cm away from <Col1>. Mount the sensor of a power meter so that the power of the reflected laser output beam can be measured continuously. The wavelength of the power meter should be set to 1,060 nm. A typical starting power reading with 0.5 W pump power is ~50 mW before alignment.

- Adjust the screws on the collimator mounts to increase the reading of the power meter. Continue making fine adjustments until the output power reaches a maximum value of about 150 mW, which indicates an excellent alignment.

NOTE: This step requires careful and patient adjustment, which is often time consuming. It is most efficient to follow a systematic systematic procedure: First, rotate the two screws that adjust the angle in the same direction (X or Y) on the two collimators, with one screw rotating very slowly in one direction while the other is rotating fast to scan all reasonable angles. Keep tracking the maximum reading from the power meter. Once the maximum power is found, switch to the screws, adjusting to another direction. Repeat the slow rotate and fast scan described above. Due to reflections from the lenses inside both collimators, it is possible to observe multiple local maxima while aligning the collimators. The actual maximum power is much greater (150 mW) compared with the local maxima (70 to 80 mW). - Mount the isolator 3 cm from <Col2>. Adjust the direction of the collimators again to align the free space components and to maximize output power. The presence of the isolator may slightly deflect the beam alignment, but the maximum output power is recovered by fine adjustments to the collimators.

- Mount the birefringent filter <BF>, a half wave plate <HWP> and two quarter wave plates (<QWP1> and <QWP2>) to the corresponding positions shown in Figure 1. The birefringent filter is sandwiched between two polarizers-one before (<PBS>) and one after (within the <ISO>)-to create a sinusoidal band-pass filter effect. There must be a small (3°−5°) incident angle for the <BF> in order to control the wavelength range. Tune the alignment of the collimators once more until the output power reaches a maximum value.

5. Set up extra-cavity components

- Splice all three ports of the splitter (Figure 1) with fiber optic connectors (FC) or SubMiniature version A (SMA) connectors. The types of connectors depend on the input ports of the photodiode and the optical spectrum analyzer (OSA). Splice steps are identical to those described in section 1 above.

- Connect one output of the splitter to the photodiode input port of the OSA and the other output to the photodiode using FC connectors.

- Connect the photodiode output port to the oscilloscope (OSC) with a Bayonet Neill-Concelman (BNC) cable.

- Connect the collimator <Col3> to the input port of the splitter.

NOTE: Using the connector to connect the splitter and <Col3> is for convenience. This connection can be replaced with a splice if desired. - Remove the power meter sensor.

- Mount the small mirror <M1> and the first compressor grating <G1> on the optical table. To achieve maximum efficiency of the compressor gratings, use the power meter to monitor the power of the first order maximum while adjusting the incident angle by rotating the grating.

NOTE: A rotational stage can be used to precisely control the rotation. As the loss due to the incident angle offset is small, the rotational stage is not used here to reduce cost. - Mount the translational stage on the table. Mount the second compressor grating <G2> on the translational stage. The distance between the gratings should be approximately 2 cm for optimal compression with fine adjustment using the translational stage. Ensure that the gratings are parallel.

- Mount the compressor mirror <M2> on the optical table. This mirror should be vertical and perpendicular to the moving direction of the translational stage.

- Mount the rest of the mirrors, the beam splitter, and the collimator <Col3>. The alignment will be adjusted later.

- Turn on the pump laser. Adjust the pump level to less than 0.5 W.

- Use an IR scope to check the splice <C>. Add index matching gel to any bright spots.

NOTE: Step 5.11 should be done regularly during the normal use of the laser. - Align the compressor.

- Use an IR card to locate the beam, adjust the position of <M1>, and the compression gratings so that the output beam traverses the pulse compression parts in the following sequence: <M1>, <G1>, <G2>, <M2>, <G2>, <G1>, <M1>.

- Tilt <M2> up slightly to raise the reflected beam, making it pass above the pulse picker mirror <M1>.

NOTE: <M2> can be replaced by a retroreflector such that the pickoff mirror <M1> need not be angled. That is, the reflected beam will be parallel to the incident beam, but displaced, using a retroreflective mirror to simplify the setup.

- Align the collimator with one output beam of the beam splitter.

- Turn on the OSA and set the device to the Power Meter mode.

- Adjust the angle of the mirror <M3> and the collimator to maximize the power input. The power reading should be above -10 dBm.

6. Attaining mode-locked performance with characterization of the laser pulse output

- Turn on the OSC and set the instrument to AC coupling mode with the trigger level set to 30 mV.

- Move the OSA photodiode input fiber to monochromatic input. Set the device to OSA mode.

- Lock the phase of the laser by adjusting the wave plates15.

- Rotate <QWP2> several degrees back and forth. The mode-locking spectrum roughly consists of two stable peaks with a plateau between them (i.e., a so-called cat-ear or Batman shape). Meanwhile, a stable pulse train can be observed on the OSC.

- If the mode-locking spectrum is not observed, rotate <QWP1> several degrees in one direction and repeat step 6.3.1.

- If the mode-locking spectrum cannot be observed by repeating 6.3.2, then rotate <BF> several degrees and repeat step 6.3.2.

NOTE: There are several characteristic modes of the laser operation that can be distinguished by observing the OSA: 1. One or two narrow (~1 nm) peaks. These are amplified spontaneous emissions (ASE). 2. A wide (~50 nm) noisy peak with broken lines appearing randomly. This is a partial mode-lock (PML) spectrum. In this noise-like pulse mode the intensity and duration of each pulse varies, which results in poor image quality unless one integrates the pulse fluctuations over longer pixel residence times.17 3. One ASE peak with a very noisy background consisting of many low-amplitude peaks. This is a non-mode-locked Q-switching mode. When in this mode, mode-locking can often be achieved by rotating <QWP1> over a small angle. 4. The Batman shaped mode-locking spectrum. The "ears" typically have different amplitudes with a flat spectrum between the sharp edge features. Davoudzadeh et al. provide detailed measurements and illustrative results for each of these modes of operation17.

- Acquire and analyze the radio frequency (RF) spectrum.

- Disconnect the BNC cable from the OSC and connect it to the RF spectrum analyzer.

NOTE: Using a BNC tee adapter is not recommended, because the ground forms a closed loop, which induces an echo within the circuit. The RF spectrum analyzer is not shown in Figure 1, because it takes the same position as the OSC when in use. - Follow the RF spectrum analyzer instruction manual to locate the primary spectrum peak. The approximate expected frequency can be calculated based on the time between two pulses using the OSC.

- Gently adjust the wave plates and birefringent filter to maximize the signal-to-noise ratio, which is the height of the primary peak relative to the background.

NOTE: The mode-locking RF spectrum should be a single peak with no side lobes. For the best imaging quality, the SNR should reach at least 70 dB. The spectrum on the OSA should be carefully monitored, keeping track of the Batman spectral shape, to ensure the laser remains mode-locked.

- Disconnect the BNC cable from the OSC and connect it to the RF spectrum analyzer.

- Follow the manufacturer instructions to align and operate the autocorrelator to measure the pulse duration. The second output from the extra-cavity beam splitter can be used. Once the pulse duration can be measured, carefully adjust the translational stage on which <G2> is mounted to adjust the distance between the two gratings to tune the duration of the pulse.

NOTE: To ease alignment, it is best to mount mirror <M1> and <M2> separately from the two gratings and the translational stage to which they are mounted. Also note that picosecond pulses are observed as a broad pedestal along with a central fs pulse peak feature during partially mode-locked operation17. - Gradually increase the pump power above 0.5 W to find the maximum pump power. Powers up to ~5W have been tested. Use the IR scope to constantly observe the active fiber <4>. If a bright spot appears, the pump power is too high within the cavity, and it is likely to burn the active fiber at this pump level.

NOTE: The maximum power of the system depends on the length of the active fiber and the alignment of the in-cavity free-space components. The protocols described here reach output powers up to 1 W without the appearance of bright spots or burns to the cavity, and this power is more than sufficient for most imaging applications. Higher output powers were not tested but may be possible, although multipulsing is likely to result16,17,18.

Representative Results

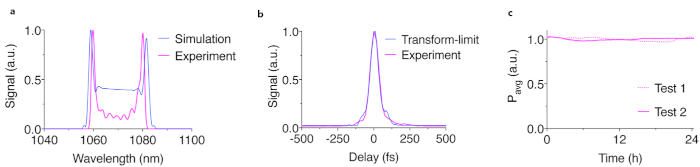

It is critical to verify mode-locked operation upon completion of the fiber laser fabrication procedures. Signatures of optimal fs pulse generation and laser stability are as follows: First, the output pulse may be sufficiently characterized by the instrumentation outlined in step 6. The pulse spectrum output from the laser oscillator should be centered near 1,070 nm with the characteristic cat-ear or Batman shape that indicates mode-locking as predicted by numerical simulation of ANDi pulse physics15 (Figure 2A). Although the characteristic spectrum is an excellent indicator of pulse coherence, additional tests are warranted to ensure full mode-locking, stability, and the expected laser performance. As a further diagnostic for mode-locking, the pulse duration and pulse repetition power spectra are measured using the autocorrelator and RF spectrum analyzer, respectively. A single peak without a pedestal is expected for both measurements during mode-locked operation. During the autocorrelation measurements, the grating pair can be tuned to achieve pulse compression. Pulse durations of 70 fs (full-width-half-maximum) were measured (Figure 2B). This dechirped pulse duration approaches the estimated transform limited compression of the present laser design: the transform limit is computed using the measured pulse spectrum. Second, pulse stability may be tested by continuously monitoring the average output power and the pulse spectrum. The power drift is less than ±3.5% over 24 h (Figure 2C) without active cooling when the laser setup is mounted on a floating optical table with vibration damping. This level of stability is sufficient for many imaging experiments. The system then remains stable and self-starting for more than a week when powered down. The free-space components undergo mechanical drift and the mode-lock is lost after several weeks, but mode-locking can often be re-obtained by minor adjustments of the waveplates as outlined in step 6.

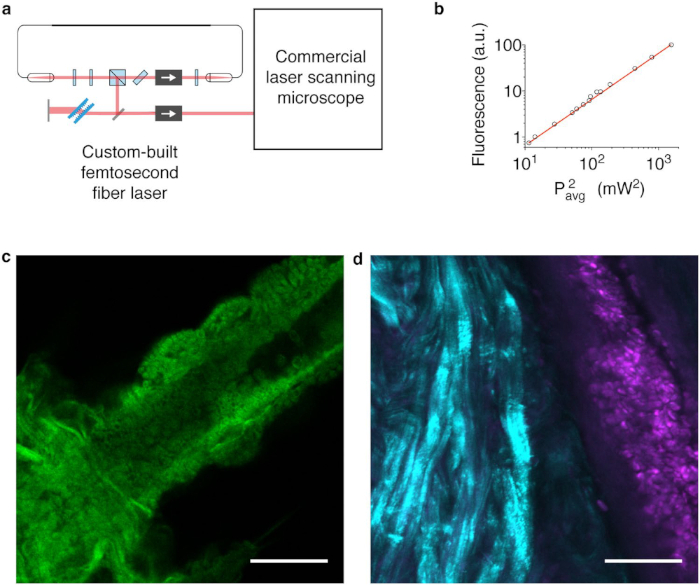

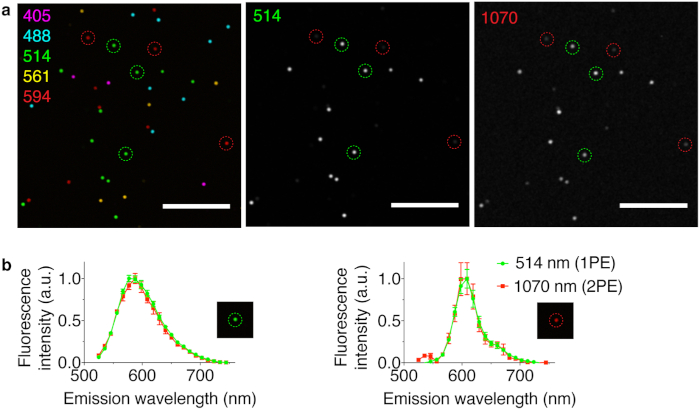

Once mode-locking is verified, it is also important to test the imaging performance during practical MPE and nonlinear microscopy experiments using simple test target and biological samples. For example, the custom fiber laser output may be directed into a commercial laser scanning microscope for two-photon excitation (2PE) fluorescence imaging (Figure 3A). Note that the extra-cavity isolator, although lossy, is necessary to prevent back reflections from the microscope optics from entering the laser oscillator. These back reflections often interrupt mode-locking and fluorescence signal generation during imaging. Here, a test was conducted with a commercial confocal laser scanning microscope and a descanned detector with a pinhole set to the maximum size setting in order to increase the collected fluorescence signal. One simple test sample for microscopy is the measurement of a fluorescent dye solution. A suggested first microscopy experiment is to measure the fluorescent dye signal during adjustments of the pulse power using a set of neutral density filters. This helps verify that the fluorescence signal is quadratically dependent on the laser power delivered to the sample plane (Figure 3B), which is the expected response for 2PE. Next, images of biological specimens may be collected usingnonlinear 2PE tissue autofluorescence, for instance (see Figure 3C, an unstained, fixed brine shrimp sample) as well as second harmonic generation (SHG) from collagen fibrils and 2PE of extrinsic fluorescent stains (see Figure 3D, a freshly excised chicken tissue specimen stained with rhodamine B). As an additional verification of 2PE, collected 2PE hyperspectral images of multicolor fluorescent microsphere test targets were compared with hyperspectral images taken by linear excitation with commercial diode lasers (Figure 4). The single-photon excitation and 2PE fluorescence spectra were analyzed and compared for two of the microsphere colors corresponding to two fluorescent dyes excited separately by commercial, continuous wave 514 nm and 594 nm lasers. The fluorescence spectra excited by the custom-built laser are identical to the spectra taken with the commercial continuous wave lasers (single-photon excitation). Collectively, these results indicate that the custom fs fiber laser generates pulses with sufficient peak power and uniformity to generate 2PE fluorescence and SHG.

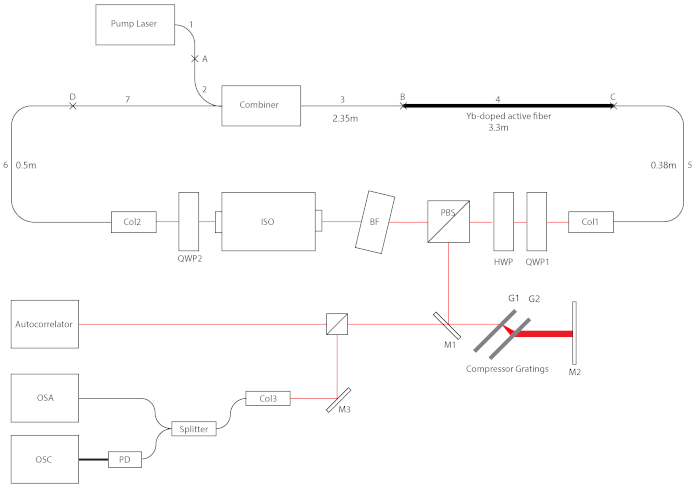

Figure 1: Schematic of the custom fiber laser and pulse characterization setup. The numbered black lines 1 and 2 indicate the pump laser output. The numbered black lines 3−7 indicate intracavity fibers with the length of each fiber between the splice points indicated in meters. The unnumbered black lines indicate extra-cavity fibers. The cross (x) marks indicate splice points. The red lines are free-space light paths. The thick black line between the OSC and the photodiode (PD) indicates a BNC cable. The RF spectrum analyzer, which takes the same position as the OSC when being used, is not shown in the figure because the RF spectrum analyzer may be swapped into the setup for the OSC using the BNC connector. Please click here to view a larger version of this figure.

Figure 2: The results of laser characterization. (A) The spectrum of the output pulse from mode-locking operation compared with numerical simulation. (B) The intensity autocorrelation signal of the dechirped pulse compared to numerical simulation of the transform limit. (C) The output power of the laser during two 24 h stability tests. (Adapted from Davoudzadeh et. al.17) Please click here to view a larger version of this figure.

Figure 3: The results of MPE microscopy performance tests. (A) Schematic of the custom-built fiber laser with its output directed into a commercial confocal microscope. (B) The log-log plot demonstrating the quadratic dependence of the MPE fluorescence signal as a function of laser output power, measured using a solution of fluorescent dye. (C) 2PE autofluorescence image of an unstained and fixed brine shrimp sample using the custom fs fiber laser. (D) SHG (cyan) of collagen fibrils and 2PE fluorescence (magenta) of rhodamine B-stained cells from a freshly excised chicken tissue using the custom fs fiber laser. Scale bars = 50 µm. (Adapted from Davoudzadeh et. al.17) Please click here to view a larger version of this figure.

Figure 4: A comparison of 2PE fluorescence using the custom fs fiber laser versus single-photon excitation (1PE) using commercial diode lasers. (A) A multichannel 1PE image of spectrally distinct microbeads using several different diode lasers (Left; 1PE wavelengths are listed in nm.) The fluorescent intensity profile of the same beads excited by a 514 nm diode laser (Middle) and by the custom fs fiber laser (Right). Scale bars = 50 µm. (B) The normalized spectra of green (left) and red (right) beads excited by the diode laser versus the custom fs fiber laser. (Adapted from Davoudzadeh et. al.17) Please click here to view a larger version of this figure.

| Splicing point | A | B | C | D |

| Left fiber index | 1 | 3 | 4 | 6 |

| L coating diameter (μm) | 250 | 250 | 250 | 250 |

| L clad diameter (μm) | 125 | 130 | 125 | 125 |

| L core diameter (μm) | 105 | 5 | 6 | 6 |

| L MFD (μm) | 105 | 4.8 | 7 | 6.2 |

| Right fiber index | 2 | 4 | 5 | 7 |

| R coating diameter (μm) | 250 | 250 | 250 | 250 |

| R clad diameter (μm) | 125 | 125 | 125 | 130 |

| R core diameter (μm) | 105 | 6 | 6 | 5 |

| R MFD (μm) | 105 | 7 | 6.2 | 4.8 |

Table 1: A summary of the parameters for the pump laser fiber splice point (A) as well as the three intracavity fiber splice points (B-D). Here the direction of light propagation is from the left fiber to the right fiber. L = left fiber in splice joint; R = right fiber in splice joint; MFD = mean field diameter.

Discussion

The protocols outlined here synthesize know-how and expertise that have been common practice in the laser physics laboratory for decades, but which is frequently unfamiliar to many biomedical researchers. This work attempts to make this ultrafast fiber laser technology more accessible to the broader community. The ANDi fiber laser design is well-established, as first developed in seminal works by Wise and colleagues3. However, implementations of this technology by other groups have sometimes resulted in reports of lasers that do not operate properly, illustrating the need to further educate biomedical researchers in nontrivial aspects of pulse characterization and mode-locked operation.

Note that custom laser fabrication and operation is generally not suitable for laboratories unfamiliar with laser operation and safety. Laser safety training and consideration of hazards is essential before attempting construction of a class 4 laser. Because the laser system is open, there are two major reflection beams (coming from the compressor gratings and the in-cavity PBS) and several minor reflections from other optics that need to be blocked. The free-space components should be secured to a stable optical table in order to maintain the alignment. In contrast, commercial lasers are always enclosed for safety and often utilize auto-alignment mechanisms, making them easier and safer to operate.

As mentioned, the custom fs fiber laser presented here represents perhaps the best performance that can be expected for an easily constructed system that minimizes material costs. The design and quality of the splices is a critical factor for the laser efficiency, ease of fabrication, and robustness to burn point damage. A low-quality splice cannot only reduce the pump output efficiency, but also generate heat during operation and, thus, damage the cavity. To achieve high-quality splices, one needs to make sure the fiber cleaver and splicer are clean. As mentioned above, cotton swabs soaked with alcohol should be used to clean all working surfaces on a regular basis. In addition, when large cleave angles (>0.3°) occur, it is strongly advised to recleave to improve the splice quality.

Once mode-locked, the system is quite stable and remains self-starting during a period of more than a week. In case of accidental perturbations in the system or mechanical drift of the free-space components over time, the system will lose mode-locking, but the mode-locking laser can often be easily recovered by slightly adjusting the wave plates. To maintain stable output, temperature control of the active fiber is key. Therefore, the system is best used in an air-conditioned room with minimal air flow near it. The system is relatively impervious to small vibrations. In fact, the effect of mechanical vibration cannot be observed in both the temporal and spectral domains if the system is put on a passive damped optical table. Touching the fiber components of the oscillator will perturb the mode-lock, but mode-locking is recovered simply by returning the fiber back to its approximate original position.

Finally, the compact form factor of fs fiber lasers is attractive for developing mobile clinical systems. (e.g., mobile cart-based systems). While smaller in size compared to a solid-state laser, the custom fiber laser design presented here contains several free-space components that require alignment. This significantly limits the mobility of the system. It is possible to replace all of these free-space components with fiber component analogs. Future work will include development of new all-fiber laser designs using PM fiber to develop systems that are robust to environmental changes.

開示

The authors have nothing to disclose.

Acknowledgements

We thank Drs. E. Cronin-Furman and M. Weitzman (Olympus Corporation of the Americas Scientific Solutions Group) for assistance in acquiring images. This work was supported by National Institutes of Health Grant K22CA181611 (to B.Q.S.) and the Richard and Susan Smith Family Foundation (Newton, M.A.) Smith Family Award for Excellence in Biomedical Research (to B.Q.S.).

Materials

| Adapters, mirrors, posts, mounts, and translational stage (optomechanics) | Thorlabs | TR6-P5 (3x), AD12NT (2x), PFSQ20-03-M01, PFSQ05-03-M01, KMS, KM100C, KM100CL, KM200S, LT1, LT101, UPH2-P5, UPH3-P5 (2x) | Standard optical components |

| Advanced optical fiber cleaver | AFL | CT-100 | |

| Autocorrelator | Femtochrome | FR-103XL/IR/FA/CDA | |

| Beamsplitter mount | Thorlabs | BSH1/M | |

| Factory fusion splicer | AFL | FSM-100P | |

| Fiber collimators | OZ Optics (Canada) | LPC-08-1064-6/125-S-1.6-7.5AS-60-X-1-2-HPC | 3x |

| Fiber-coupled,high-speed photodiode detector | Thorlabs | DET08CFC | |

| Free-space isolator | Thorlabs | IO-5-1050-HP | |

| Free-space isolator | Thorlabs | IO-3D-1050-VLP | |

| Half waveplate | Union Optics (China) | WPZ2312 | 2x |

| High power multimode fiber pump module | Gauss Lasers (China) | Pump-MM-976-10 | |

| High power pump and signal combiner | ITF Technology (Canada) | MMC02112DF1 | |

| Index matching gel | Thorlabs | G608N3 | |

| Optical spectrum analyzer | Keysight | Agilent 70951B | |

| Oscilloscope | Keysight | Agilent 54845A | |

| Passive double clad fiber(5/130 μm) | ITF Technology (Canada) | MMC02112DF1 | 3m, Included with combiner |

| Polarizing beamsplitter | Thorlabs | PBS253 | |

| Quarter waveplates | Union Optics (China) | WPZ4312 | 2x |

| Quartz birefringent filter plate | Newlight (Canada) | BIR1060 | |

| RF spectrum analyzer | Tektronix | RSA306B | |

| Single mode fiber (6/125 μm) | OZ Optics (Canada) | LPC-08-1064-6/125-S-1.6-7.5AS-60-X-1-2-HPC | 1m, Included with collimators |

| Single mode fiber coupler | AFW (Australia) | FOSC-2-64-30-L-1-H64-2 | |

| Transmission diffraction grating 1 | LightSmyth | T-1000-1040-3212-94 | For compressor |

| Transmission diffraction grating 2 | LightSmyth | T-1000-1040-60×12.3-94 | For compressor |

| Waveplate rotation mount | Thorlabs | RSP1/M | 4x |

| Ytterbium-doped single mode double clad fiber | Thorlabs | YB1200-6/125DC | 3m |

参考文献

- Savage, N. Optical parametric oscillators. Nature Photonics. 4, 124 (2010).

- Xu, C., Wise, F. Recent advances in fibre lasers for nonlinear microscopy. Nature Photonics. 7, 875 (2013).

- Kieu, K., Wise, F. All-fiber normal-dispersion femtosecond laser. Optics Express. 16, 11453-11458 (2008).

- Fekete, J., Cserteg, A., Szipőocs, R. All-fiber all-normal dispersion ytterbium ring oscillator. Laser Physics Letters. 6, 49-53 (2009).

- Krolopp, &. #. 1. 9. 3. ;., et al. Handheld nonlinear microscope system comprising a 2 MHz repetition rate, mode-locked Yb-fiber laser for in vivo biomedical imaging. Biomedical Optics Express. 7, 3531-3542 (2016).

- Fermann, M. E., Hartl, I. Ultrafast fibre lasers. Nature Photonics. 7, 868-874 (2013).

- Szczepanek, J., Kardaś, T. M., Michalska, M., Radzewicz, C., Stepanenko, Y. Simple all-PM-fiber laser mode-locked with a nonlinear loop mirror. Optics Letters. 40, 3500-3503 (2015).

- Bowen, P., Singh, H., Runge, A., Provo, R., Broderick, N. G. Mode-locked femtosecond all-normal all-PM Yb-doped fiber laser at 1060 nm. Optics Communications. 364, 181-184 (2016).

- Chong, A., Buckley, J., Renninger, W., Wise, F. All-normal-dispersion femtosecond fiber laser. Optics Express. 14, 10095-10100 (2006).

- Kieu, K., Renninger, W., Chong, A., Wise, F. Sub-100 fs pulses at watt-level powers from a dissipative-soliton fiber laser. Optics Letters. 34, 593-595 (2009).

- Wise, F. W. Femtosecond Fiber Lasers Based on Dissipative Processes for Nonlinear Microscopy. IEEE Journal of Selected Topics in Quantum Electronics. 18, 1412-1421 (2012).

- Nielsen, C. K., Keiding, S. R. All-fiber mode-locked fiber laser. Optics Letters. 32, 1474 (2007).

- Liu, Z., Ziegler, Z. M., Wright, L. G., Wise, F. W. Megawatt peak power from a Mamyshev oscillator. Optica. 4, 649-654 (2017).

- Sidorenko, P., Fu, W., Wright, L. G., Olivier, M., Wise, F. W. Self-seeded, multi-megawatt, Mamyshev oscillator. Optics Letters. 43, 2672-2675 (2018).

- Li, X., et al. High-power ultrafast Yb:fiber laser frequency combs using commercially available components and basic fiber tools. Review of Scientific Instruments. 87, 093114 (2016).

- Bale, B., Kieu, K., Kutz, J., Wise, F. Transition dynamics for multi-pulsing in mode-locked lasers. Optics Express. 17, 23137-23146 (2009).

- Davoudzadeh, N., Ducourthial, G., Spring, B. Q. Custom fabrication and mode-locked operation of a femtosecond fiber laser for multiphoton microscopy. Scientific Reports. 9, 4233 (2019).

- Renninger, W., Chong, A., Wise, F. W. Area theorem and energy quantization for dissipative optical solitons. Journal of the Optical Society of America. 27, 1978-1982 (2010).