Synthesis of Single-Crystalline Core-Shell Metal-Organic Frameworks

Summary

Here, we demonstrate a protocol for the two-step synthesis of single-crystalline core-shells using a non-isostructural metal-organic framework (MOF) pair, HKUST-1 and MOF-5, which have well-matched crystal lattices.

Abstract

Because of their designability and unprecedented synergistic effects, core-shell metal-organic frameworks (MOFs) have been actively examined recently. However, the synthesis of single-crystalline core-shell MOFs is very challenging, and thus a limited number of examples have been reported. Here, we suggest a method of synthesizing single-crystalline HKUST-1@MOF-5 core-shells, which is HKUST-1 at the center of MOF-5. Through the computational algorithm, this pair of MOFs was predicted to have the matched lattice parameters and chemical connection points at the interface. To construct the core-shell structure, we prepared the octahedral- and cubic-shaped HKUST-1 crystals as a core MOF, in which the (111) and (001) facets were mainly exposed, respectively. Via the sequential reaction, the MOF-5 shell was well-grown on the exposed surface, showing a seamless connect interface, which resulted in the successful synthesis of single-crystalline HKUST-1@MOF-5. Their pure phase formation was proved by optical microscopic images and powder X-ray diffraction (PXRD) patterns. This method presents the potential of and insights into the single-crystalline core-shell synthesis with different kinds of MOFs.

Introduction

MOF-on-MOF is a type of hybrid material comprising two or more different metal-organic frameworks (MOFs)1,2,3. Owing to the various possible combinations of constituents and structures, MOF-on-MOFs provide varied novel composites with remarkable properties, which have not been achieved in single MOFs, offering great potential in many applications4,5,6. Among the various types of MOF-on-MOFs, a core-shell structure in which one MOF surrounds another has the advantage of optimizing the characteristics of both MOFs by designing a more elaborated system5,6,7,8,9,10. Although many examples of core-shell MOFs have been reported, single-crystalline core-shell MOFs are uncommon and have been successfully synthesized mostly from isostructural pairs11,12,13. Moreover, single crystalline core-shell MOFs constructed using non-isostructural MOF pairs have seldom been reported, owing to the difficulty in selecting a pair that exhibit a well-matched crystal lattice3. To achieve seamless interfaces of the single-crystalline core-shell MOFs, a well-matched crystal lattice and chemical connection points between the two MOFs are critical. Here, the chemical connection point is defined as the spatial location where the linker/metal node of one MOF meets the metal node/linker of the second MOF through a coordination bond. In our previous reports14, the computational algorithm was used to screen for optimal targets for synthesis, and six suggested MOF pairs were successfully synthesized.

This paper demonstrates a protocol for synthesizing a single-crystalline core-shell MOF of an HKUST-1 and MOF-5 pair, which are iconic MOFs composed of totally different constituents and topologies. HKUST-1 was chosen as the core because it is more stable than MOF-5 under solvothermal reaction conditions15,16. Furthermore, because the chemical connection points between MOF-5 and HKUST-1 are well-matched in both the (001) and (111) planes, cubic and octahedral HKUST-1 crystals in which each plane is exposed were used as the core MOF. This protocol suggests the possibility of synthesizing more diverse core-shell MOFs with lattice-matching.

Protocol

CAUTION: Before conducting the experiment, thoroughly read and comprehend the material safety data sheets (MSDSs) of the chemicals used in this protocol. Wear appropriate protective gear. Utilize a fume hood for all synthesis procedures.

1. Synthesis of cubic HKUST-1

NOTE: The experimental procedure was based on a previously reported method14. For core-shell synthesis, 10 pots were synthesized at a time. Therefore, 10 pots of the solution were prepared at one time and then distributed.

- Add 4.72 g (20.3 mmol) of Cu(NO3)2·2.5H2O to a 100 mL Erlenmeyer flask and dissolve in 60 mL of a deionized (D.I.) water and N,N-dimethylformamide (DMF) mixture (1:1, v/v), swirling the flask manually.

- Add 1.76 g (8.38 mmol) of 1,3,5-benzenetricarboxylic acid (H3BTC) and 22 mL of ethanol to a 50 mL Erlenmeyer flask, and stir the solution at 90 °C on a heated hotplate until dissolution.

- Place 6 mL of solution 1.1 (solution prepared in step 1.1) into each 20 mL vial.

- While stirring and heating, add 2.2 mL of solution 1.2 (solution prepared in step 1.2) to a vial containing solution 1.1, and immediately add 12 mL of acetic acid.

NOTE: 12 mL of acetic acid should be added at once. - Close the lid of the vial and place it in a convection oven heated to 55 °C for 60 h.

- After 60 h, quickly decant the mother liquor and wash the crystals by adding and removing fresh ethanol (sufficient volume to fill the vial) three times using a dropper.

- For core-shell synthesis, store the cubic crystals of HKUST-1 in a 20 mL vial full of N,N-diethylformamide (DEF) solvent.

2. Synthesis of octahedral HKUST-1

- Combine 4.72 g (20.3 mmol) of Cu(NO3)2·2.5H2O and 30 mL of D.I. water in a 100 mL Erlenmeyer flask, swirl the flask to dissolve the solid, and add 30 mL of DMF after dissolving.

- Add 3.60 g (17.1 mmol) of H3BTC to 45 mL of ethanol in a 100 mL Erlenmeyer flask, and stir the solution at 90 °C on a heated hotplate until dissolution.

- Place 6 mL of solution 2.1 (solution prepared in step 2.1) into each 50 mL vial.

- While stirring and heating, add 4.5 mL of solution 2.2 (solution prepared in step 2.2) to a vial containing solution 2.1, and immediately add 12 mL of acetic acid.

NOTE: 12 mL of acetic acid should be added at once without dividing. - Close the lid of the vial and place in a convection oven heated to 55 °C for 22 h.

- After 22 h, quickly decant the mother liquor and wash the crystals by adding and removing fresh ethanol three times using a dropper.

- For core-shell synthesis, store octahedral crystals of HKUST-1 in a 20 mL vial full of DEF solvent.

3. Synthesis of HKUST-1@MOF-5 core-shell

NOTE: The core-shell synthesis method is the same for both octahedral and cubic HKUST-1.

- Dissolve 0.760 g (2.55 mmol) of Zn(NO3)2·6H2O and 0.132 g (0.795 mmol) of terephthalic acid separately in 10 mL of DEF in a 20 mL vial, using a sonicator.

- Mix the total volume of both solutions in a 35 mL glass jar.

- Quickly weigh the filtered HKUST-1 crystals (5 mg), and place the crystals in the glass jar containing the mixed solution. To prevent static electricity, use a filter paper to weigh. Seal the jar tightly with a silicon cap.

- After spreading the HKUST-1 crystals well on the bottom of the glass jar, place the jar in a convection oven and heat at 85 °C for 36 h.

- After 36 h, quickly decant the mother liquor and wash the resultant crystals by adding and removing fresh ethanol three times using a dropper.

4. Solvent exchange of HKUST-1@MOF-5 core-shell

- Discard the storing solvent, DEF, from the vial containing HKUST-1@MOF-5.

- Add dichloromethane (DCM) (volume to fill the vial) into the vial and shake it manually for effective exchange.

- Change the DCM solvent 3-4 times every 4 h.

Representative Results

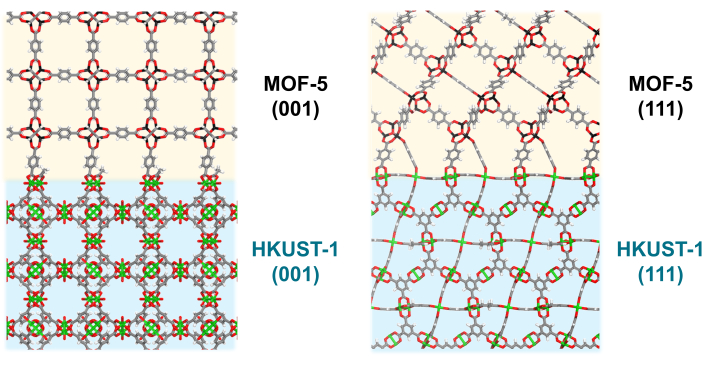

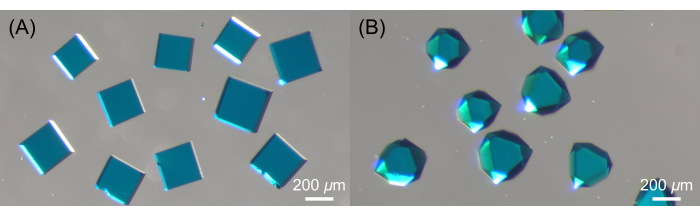

According to the two calculated structures of the HKUST-1@MOF-5 core-shell system14, in both the (001) and (111) planes, the Cu sites from the metal nodes of HKUST-1 and the oxygen sites from the carboxylates of MOF-5 are well-matched as the chemical connection points at the interface between the two MOFs (Figure 1). Therefore, cubic and octahedral crystals of HKUST-1, in which the (001) and (111) planes are exposed, respectively, were synthesized as the core MOFs for core-shell synthesis (Figure 2). The optical microscope images revealed that the synthesized HKUST-1 crystals were ~300 µm and ~150 µm in size with cubic and octahedral shapes, respectively.

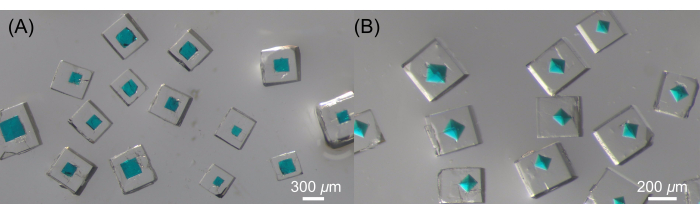

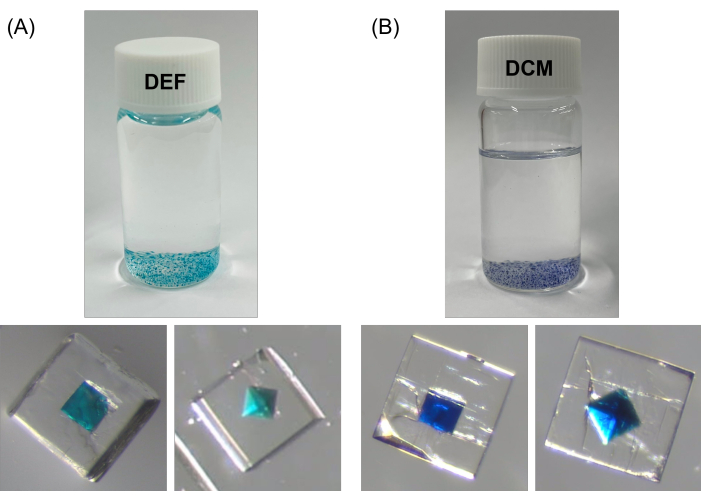

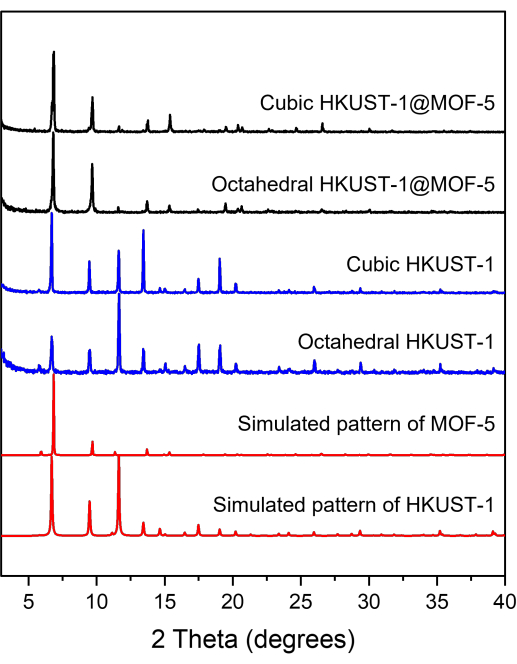

The HKUST-1@MOF-5 synthesis was carried out in a glass jar, and the well-dispersed HKUST-1 core reacted with the MOF-5 precursors for successful core-shell synthesis (Figure 3). Figure 4 and Figure 5 show the single crystalline HKUST-1@MOF-5; the HKUST-1 crystal is located in the center of the colorless MOF-5 crystal with a seamless interface to provide a core-shell structure. PXRD measurements (Figure 6) proved the phase purity of the core-shell crystal. The highest peaks appeared at 6.7° and 11.7° for cubic and octahedral HKUST-1, respectively, indicating that the (200) and (222) planes were mainly exposed on the HKUST-1 surface, implying successful synthesis. The HKUST-1 core crystal can change its color from green to dark blue by guest molecule coordination. Notably, a solvent exchange experiment from DEF to DCM revealed a solvent-accessible interface with a good connection, as described in the modeled structure (Figure 1).

Figure 1: Computational structure models. Computational structure models for the HKUST-1@MOF-5 system at the (001) (left) and (111) (right) plane. This figure has been modified from Kwon et al.14. Please click here to view a larger version of this figure.

Figure 2: Optical microscope images. (A) Cubic-shaped HKUST-1 and (B) octahedral-shaped HKUST-1. Scale bars: 200 µm. Please click here to view a larger version of this figure.

Figure 3: Photographs of HKUST-1 in glass jars. Image of a glass jar containing well-dispersed HKUST-1 crystals at the bottom. Please click here to view a larger version of this figure.

Figure 4: Optical microscope images of the HKUST-1@MOF-5 core-shell. Images of the HKUST-1@MOF-5 core-shell, synthesized using (A) cubic- and (B) octahedral-shaped HKUST-1. Scale bar in panel A is 300 µm and panel B is 200 µm. Please click here to view a larger version of this figure.

Figure 5: Photographs and optical microscope images of HKUST-1@MOF-5. (A) Photographs of HKUST-1@MOF-5 in DEF and corresponding optical images of the core-shell MOF using cubic- (left) and octahedral-shaped (right) HKUST-1. (B) Photographs of HKUST-1@MOF-5 in DCM and corresponding optical images of core-shell MOF using cubic- (left) and octahedral-shaped (right) HKUST-1. Please click here to view a larger version of this figure.

Figure 6: PXRD patterns. PXRD patterns of HKUST-1 (blue) and HKUST-1@MOF-5 (black) with cubic- and octahedral-shaped HKUST-1, and simulated patterns of HKUST-1 and MOF-5 (red). Please click here to view a larger version of this figure.

Discussion

In this protocol, cubic- and octahedral-shaped HKUST-1 crystals were synthesized, referring to a previously reported method14. For the synthesis of HKUST-1, H3BTC solution was added while heating and stirring the solution of Cu(NO3)2·2.5H2O to prevent the precipitation of H3BTC as the temperature decreased. Subsequently, acetic acid was added immediately to prevent fast nucleation and ensure the growth of a large single crystal. As soon as the vial was taken out of the oven, the hot mother liquor was quickly discarded to prevent unwanted additional crystallization. The resultant crystals were washed with ethanol three times, and stored in fresh DEF for core-shell synthesis.

For core-shell synthesis, HKUST-1 crystals were dropped with a plastic dropper on filter paper to quickly remove the solvent on the crystal surface for weighing. The core crystal should be well spread on the bottom of the glass jar before placing in the oven, providing a sufficient surface for effective shell growth and singly grown core-shell crystals. For well dispersion, the glass jar was swirled to gather the crystals in the center of the reaction vessel and lightly tapped to spread the crystals upward. After the reaction, the mother liquor was discarded quickly, and the synthesized core-shell crystals were carefully removed with a plastic dropper and stored in fresh DEF.

Most reported core-shell synthesis methods involve the secondary growth of the shell MOF using core MOFs as a seed5,6,7,11,17,18. For the secondary growth of single-crystalline crystals, it is essential that the reaction does not damage the core. Therefore, the selection of a stable core MOF during the solvothermal synthesis condition is essential for this protocol. The details of the core-shell MOF synthesis presented herein suggest several pathways for the two-step synthesis of single-crystalline core-shell MOFs, and can be expanded to other MOF-on-MOF synthesis such as HKUST-1@IRMOF-18, UiO-67@HKUST-1, PCN-68@MOF-5, UiO-66@MIL-88B(Fe), and UiO-67@MIL-88C(Fe)14.

Divulgaciones

The authors have nothing to disclose.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Ministry of Science and the ICP (No. NRF-2020R1A2C3008908 and 2016R1A5A1009405).

Materials

| Acetic acid | DAEJUNG | 1002-4400 | Synthesis of HKUST-1 (protocol steps 1.4, and 2.4) |

| Copper(II) nitrate hemipentahydrate | Sigma Aldrich | 223395-100G | Synthesis of HKUST-1 (protocol steps 1.1, and 2.1) |

| D2 PHASER | Bruker AXS | DOC-B88-EXS017-V3 | Powder X-ray diffraction |

| Digital stirring hot plate | Thermo Scientific | SP131320-33Q | Hotplate for heating and stirring (protocol steps 1.2, and 2.2) |

| Direct-Q3UV water purification system | MILLIPORE | ZRQSVP030 | Deionized water (protocol steps 1.1, and 2.1) |

| Ethyl alcohol anhydrous, 99.9% | DAEJUNG | 4023-4100 | Synthesis of HKUST-1 (protocol steps 1.2, and 2.2) |

| Forced convection oven (OF-02P/PW) | JEIO TECH | EDA8136 | Oven for heating reaction (protocol steps 1.5, 2.5, and 3.4) |

| N,N-diethylformamide | TCI | D0506 | Synthesis of HKUST-1@MOF-5 (protocol step 3.1) |

| N,N'-Dimethylformamide | DAEJUNG | 6057-4400 | Synthesis of HKUST-1 (protocol steps 1.1, and 2.1) |

| Stereo microscopes | Nikon | SMZ745T | Optical Microscope |

| Terephthalic acid | Sigma Aldrich | 185361-500G | Synthesis of HKUST-1@MOF-5 (protocol step 3.1) |

| Trimesic acid | Sigma Aldrich | 482749-100G | Synthesis of HKUST-1 (protocol steps 1.2, and 2.2) |

| Ultrasonic cleaner | BRANSONIC | CPX-952-338R | Sonicator with bath for dissolving solution (protocol step 3.1) |

| Zinc nitrate hexahydrate | Sigma Aldrich | 228737-100G | Synthesis of HKUST-1@MOF-5 (protocol step 3.1) |

Referencias

- Liu, C., Wang, J., Wan, J., Yu, C. MOF-on-MOF hybrids: Synthesis and applications. Coordination Chemistry Reviews. 432, 213743 (2021).

- Hong, D. H., Shim, H. S., Ha, J., Moon, H. R. MOF-on-MOF architectures: Applications in separation, catalysis, and sensing. Bulletin of the Korean Chemical Society. 42 (7), 956-969 (2021).

- Ha, J., Moon, H. R. Synthesis of MOF-on-MOF architectures in the context of interfacial lattice matching. CrystEngComm. 23 (12), 2337-2354 (2021).

- Lee, S., Oh, S., Oh, M. Atypical hybrid metal-organic frameworks (MOFs): A combinative process for MOF-on-MOF growth, etching, and structure transformation. Angewandte Chemie International Edition. 59 (3), 1327-1333 (2020).

- Li, T., Sullivan, J. E., Rosi, N. L. Design and preparation of a core-shell metal-organic framework for selective CO2 capture. Journal of the American Chemical Society. 135 (27), 9984-9987 (2013).

- Cho, S., et al. Interface-sensitized chemiresistor: Integrated conductive and porous metal-organic frameworks. Chemical Engineering Journal. 449, 137780 (2022).

- Faustini, M., et al. Microfluidic approach toward continuous and ultrafast synthesis of metal-organic framework crystals and hetero structures in confined microdroplets. Journal of the American Chemical Society. 135 (39), 14619-14626 (2013).

- Boone, P., et al. Designing optimal core-shell MOFs for direct air capture. Nanoscale. 14 (43), 16085-16096 (2022).

- Yang, X., et al. One-step synthesis of hybrid core-shell metal-organic frameworks. Angewandte Chemie Edition. 57 (15), 3927-3932 (2018).

- Kim, S., Lee, J., Jeoung, S., Moon, H. R., Kim, M. Surface-deactivated core-shell metal-organic framework by simple ligand exchange for enhanced size discrimination in aerobic oxidation of alcohols. Quimica. 26 (34), 7568-7572 (2020).

- Koh, K., Wong-Foy, A. G., Matzger, A. J. MOF@MOF: microporous core-shell architectures. Chemical Communications. (41), 6162-6164 (2009).

- Luo, T. -. Y., et al. Multivariate stratified metal-organic frameworks: diversification using domain building blocks. Journal of the American Chemical Society. 141 (5), 2161-2168 (2019).

- Tang, J., et al. Thermal conversion of core-shell metal-organic frameworks: a new method for selectively functionalized nanoporous hybrid carbon. Journal of the American Chemical Society. 137 (4), 1572-1580 (2015).

- Kwon, O., et al. Computer-aided discovery of connected metal-organic frameworks. Nature Communications. 10 (1), 3620 (2019).

- Yuan, S., et al. Stable metal-organic frameworks: Design, synthesis, and applications. Advanced Materials. 30 (37), 1704303 (2018).

- Feng, L., et al. Uncovering two principles of multivariate hierarchical metal-organic framework synthesis via retrosynthetic design. ACS Central Science. 4 (12), 1719-1726 (2018).

- Furukawa, S., et al. Heterogeneously hybridized porous coordination polymer crystals: fabrication of heterometallic core-shell single crystals with an in-plane rotational epitaxial relationship. Angewandte Chemie International Edition. 48 (10), 1766-1770 (2009).

- Guo, C., et al. Synthesis of core-shell ZIF-67@Co-MOF-74 catalyst with controllable shell thickness and enhanced photocatalytic activity for visible light-driven water oxidation. CrystEngComm. 20 (47), 7659-7665 (2018).