Fabrication of Flat-Interface Nerve Electrodes for Recording Neural Activity

Abstract

Source: Dweiri, Y. M., et al. Fabrication of high contact-density, flat-interface nerve electrodes for recording and stimulation applications. J. Vis. Exp. (2016)

This video demonstrates the fabrication of a flat nerve-wrapping electrode. It showcases the integration of shielding metal and precise polymer layering for an effective recording surface. The process involves attaching, curing, trimming, and cutting polymer layers for optimal nerve contact and accurate signal recording.

Protocol

1. Electrode Components Preparation

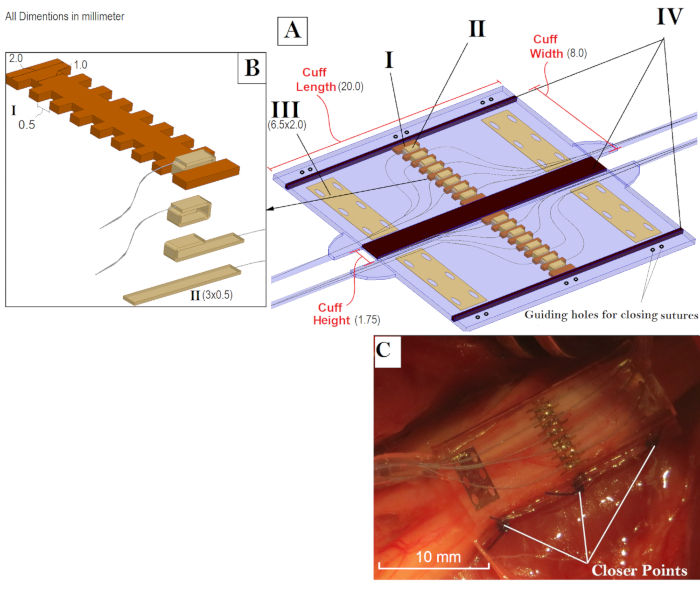

- Gather four electrode components that require precision cutting (laser cutting was used; please refer to the Materials List) before manufacturing. These components are (Figure 1):

Contacts array frame: This frame comprises a 125 µm thick Polyether ether ketone (PEEK) sheet. It covers the entire width of the cuff and holds the middle contacts and has serpentine-shaped edges (Figure 1B). The middle contacts are wrapped in the guide channels; hence the exposed width of the contacts is limited by the width of the channels and the spacing is determined by the spacing between the channels.

The middle contacts strips: The middle contacts are formed by wrapping these strips around the contacts array frame (Figure 1B). Cut the strips out of the Platinum/10% Iridium sheet to the width of the guiding channels and add extra length to allow them to be fully folded around the frame. Spot-weld the contact's lead at 0º angle with the strip's major axis.

The reference contacts: Four references are needed. The long dimension of these contacts is slightly shorter than the cuff width to fully contain them inside the cuff. Spot weld each reference contact to a lead at a 90º angle with the contact's major axis.

PEEK spacers: Spacers create a thinner region on the electrode to allow bending and closing (Figure 1C). All the spacers are made from PEEK (other materials could be used) and cut to the length of the electrode. The width of the middle space is equal to the height of the electrode.

2. Contacts Array Preparation

- Clean the components made in step 1 by sonication in ethanol for 2 min at 40 KHz and room temperature, then 2 min in distilled deionized water under the same sonication parameters. Let dry.

- Visually inspect the contacts for any defects like laser-cut residuals or surface deformations.

- Position the contacts one by one under the microscope with the welding spot facing up. Starting from the free end, hold the contact with tweezers at approximately 1/3 of its length. Elevate the lead to a 45º angle while holding the contact to make the first bend.

- Place the pre-bent contact underneath the array frame with the weld facing up. Hold the frame down with tweezers and elevate the lead to a 45º angle to make a second bend. While Continuing to hold the frame down, grab the free end of the contact with tweezers and bend at a 180º angle (fold toward the middle line of the frame).

- Straighten and pull the contact toward the operator and then bend at a 180º angle (fold to the middle line). The spot welding point should now be enclosed in between the two bent ends.

- Repeat steps 2.3 – 2.5 for the remaining contacts. Make it as tight as possible. Alternate the contact leads on each side of the array frame.

3. Cuff Layout Guide

- Create a 2D diagram of the cuff in a flat open position.

NOTE: Use any CAD (Computer-aided design) software to produce a true-scale diagram. This diagram will determine the electrode dimensions and the placement site for the various electrode components. - Print the 2D diagram on regular paper to scale using an ordinary printing machine, then cut out a 5 cm by 5 cm square piece with the drawing in the center.

- With a scalpel, cut out a 5 cm by 5 cm square piece of the thermal transparency sheet (T1).

- Place the transparency piece T1 on top of the diagram paper, and then place both layers on the base plate with the diagram facing up. Tape them down to the base plate with adhesive tape.

4. Electrode Base Layer and Reference Contacts Placement

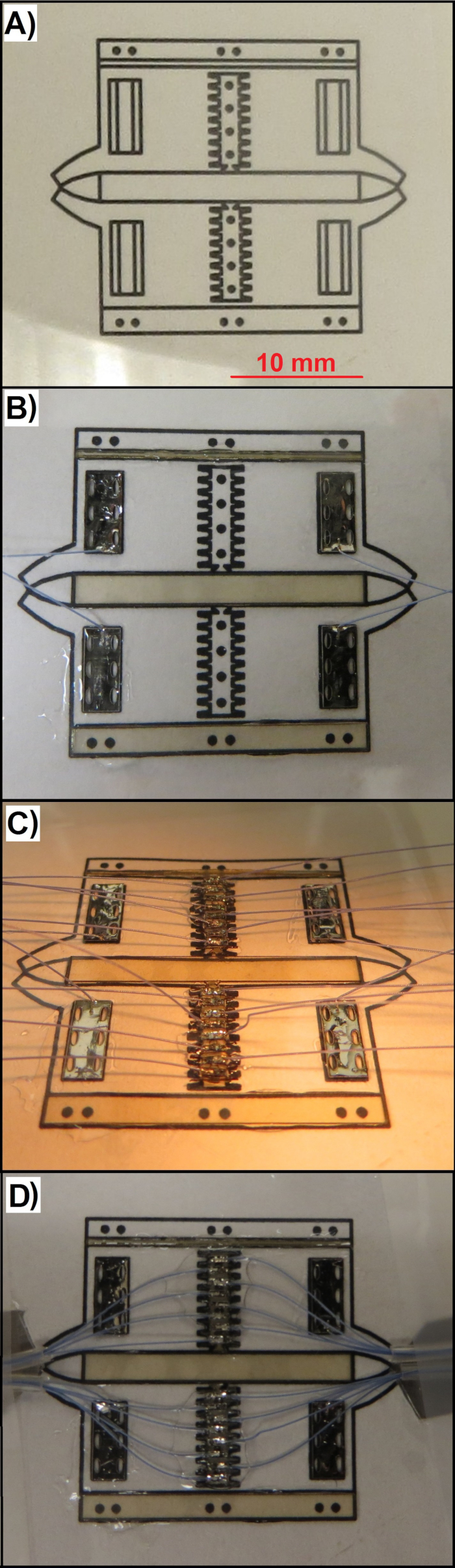

- Cut out a 5 cm by 5 cm silicone sheet with a scalpel (S1) and place it on the transparency layer. Start by dropping one corner, then slowly lower the rest of the sheet to avoid trapping air bubbles between the T1 and S1 sheets (Figure 2A).

- Mix approximately 2 g of uncured silicone as the manufacturer's datasheet directs. Rigorously stir the two parts together with a sterilized wooden stirring stick. Place the mix in a vacuum chamber for 3 min. Cycle the vacuum to eliminate the bubbles as they rise to the surface. Preheat the isotemp oven to 130 ºC.

Note: Latex gloves can inhibit the curing process of silicone. They also contain sulfur, which can leave contaminants on the working surfaces. It is recommended that you use nitrile gloves instead. - Using the dental pick tool, apply a thin line of uncured silicone along the middle of the spacer segments where they are located on the guiding diagram.

- Place the spacers onto the designated regions, and then press them down against the silicone sheet S1.

- Partially cure the silicone in the isotemp oven for 30 min, let it cool down for 10 min.

- Place the reference contacts onto designated areas. Ensure that the weld points are facing up and contact leads are routed towards the midline of the cuff to exit at the far end. After ensuring correct positioning, press the contacts down onto the silicone layer S1. Deposit uncured silicone into the through-holes.

- Tape down the leads and then fully cure the silicone at 130 ºC for 90 min, or overnight at room temperature (Figure 2B).

5. Center Contacts Array Placement

- Cut out 1.5 cm by 5 cm transparency piece with a scalpel (T2). Tape down the reference leads away from the middle region to prevent them from running underneath the contacts array during the next step.

- Place the contact arrays on the dedicated location with the leads side facing up. Deposit uncured silicone to tack the array in place.

- Place the piece from 5.1 (T2) across the midline of the electrode and over the arrays to hold them down. Tape the ends while pressing down on the arrays. Manually align the array with the dedicated position. Tape down the leads outside the cuff's perimeter.

- Place the small fixture bar across the center of the electrode and over the transparency segment T2. Clamp it down to the base plate with moderate pressure to press the middle contacts against the base silicone layer S1.

- Fully cure the silicone for 90 min at 130 ºC or overnight at RT.

6. Embedding the Electrode Components

- Remove the small fixture bar and gently remove the transparent sheet T2 to expose the middle contact arrays. Remove all the tapes holding the leads for references and middle contacts (Figure 2C).

- With a scalpel, cut a square piece of the transparency sheet to the same width as the electrode and 5 cm in length (T3), and then cut a square piece of silicone sheet to cover the entire electrode surface (S2).

- Lay the silicone sheet (S2) on top of the transparency piece (T3) and stretch it to remove any waves or irregularities and to eliminate air bubbles from being trapped in between.

- Cut four pieces of silicone tubing; 5 cm long each. Place them on the exit site of the leads as assigned on the guiding diagram. Leave a 2 mm space between the electrode and tube edges. While holding down each pair of tubes with tweezers, tape down the tubes starting at 1 mm away from the tube end. Repeat for the other pair.

- Arrange and lead of the middle contacts and the references into bundles, and then pass them through the corresponding tube near the exit sites. Repeat for the other three tubes. (Figure 2D).

- Deposit a generous amount of uncured silicone over the entire electrode body.

NOTE: Avoid forming air bubbles during this step by either slowly pouring the uncured silicone from the vacuumed mixing container or injecting it with a syringe. - Place the structure from 6.3 on top of the deposited uncured silicone with the silicone sheet S2 facing down. Align the transparency piece T3 with the electrode while keeping the silicone sheet S2 adhered to it.

- Tape down the transparency piece T3 and then apply pressure to channel out any trapped air bubbles. Place the large fixture bar across the center of the electrode and over the transparency segment T3. Then, clamp it down to the base plate with moderate pressure. Fully cure the silicone for 90 min at 130 ºC, or overnight at RT.

7. Shielding Layer Placement (Recommended for Recording Cuffs)

- Remove the large fixture bar and delaminate the transparency piece (T3) with tweezers. Place the shielding sheet in the center of each face of the electrode and apply slight pressure to press them into the electrode. Deposit uncured silicone into the through-holes.

- Partially cure the silicone for 30 min at 130 ºC, and then let it cool completely to room temperature. Place adhesive tape over the outer ends of the electrode and over the closing flanges to prevent adding extra uncured silicone to these segments.

- Repeat steps 6.6 through 6.8.

8. Cutting out the Finished Electrode

- Peel off and cut the excess silicone on top of the adhesive tape added in step 7.2 using a scalpel blade, then carefully remove the adhesive tape.

- Cut out windows through the silicone to expose the spacer segments through the S2 layer. Extract the embedded spacer segments with tweezers. This step will leave voids and form a flexible single silicone sheet at these regions (originally S1).

- Peel off the excess silicone on top of the adhesive tapes that cover the silicone tubes, and then cut it with a scalpel blade to level the tubes with the electrode body.

- Cut around the perimeter of the electrode down to the base plate.

- Cut out a triangle between each tube pair completely through the base plate. On the outer side, follow the guiding diagram to shape the leads' exit sites. Remove all the silicone material that was detached from the electrode body during the last steps.

9. Exposing Contacts and Shielding Layers

- Cut out windows through the silicone layer S2 that covers the shielding layer. Glide the polypropylene suture filament in between the electrode base (layer S1) and the transparent layer T1 on the base plate to delaminate the finished cuff electrode.

- Flip the electrode so that the center contacts and the silicone layer S1 are facing up, and then expose them by cutting out windows through the base silicone layer S1. Repeat this for the outer reference contacts, exposing 1 mm wide segments along the center of the contacts. Ensure that the stabilizing through-holes at the sides of the reference contacts are fully embedded inside the electrode's body.

10. Soldering a Connector to the Leads

- Deposit the soldering substance separately onto the leads and connecter pins, and then heat and fuse both parts together with a soldering iron.

Note: The DFT lead wires consist of a silver core surrounded by an outer layer made from the Nickel-Cobalt base alloy MP35N. Depositing the solder substance onto these wires requires the use of specialty flux to allow adhering to the wire (please refer to the Materials List).

Representative Results

Figure 1: Overview of the FINE and its Components. A) FINE in the open position and the four main building components that require precision cut. These components are: Contacts array frame (I), the middle contacts strips (II), the reference contacts (III), PEEK spacers (IV). The cuff is facing downward with respect to the contacts placement against the nerve. The spacers (IV) are removed after the assembly. B) An expanded view of the center contacts and the steps to fold and fix them around the middle frame. C) Folded configuration of the electrode.

Figure 2: Snapshots of the Electrode during the Fabrication Process. A) The guiding diagram, T1 and S1 stacks at the end of step 4.1. B) Mounting the spacer segments and reference contacts at the end of step 4.7. C) Adhering the center contacts array to S1 sheet at the end of step 6.1. D) Arranging the leads and silicone tube before embedding them inside the electrode body at the end of step 6.5.

Offenlegungen

The authors have nothing to disclose.

Materials

| Platinum-Iridium foil | Alfa Aesar | 41802 | 90%Platinum Iridium |

| DFT wires | Fort Wayne Metals | 35N LT-DFT-28%Ag | |

| Lead connector | Omnetics Connector Corporation | MCS-27-SS | |

| Silicone sheet | Speciality Silicon Fabricator | 0.005"x12"x12" Silicone Sheet | High durometer, vulcanized |

| Polyether ether ketone (PEEK) sheet | Peek-Optima | 0.005 sheet LT3 grade | |

| polyester stabelizing mesh | Surgicalmesh | PETKM2002 | |

| Silicon tubing (0.04" I.D. 0.085" O.D.) | Silcon Medical/NewAge Industries. | 2810458 | |

| Outer shielding layer | Alfa Aesar, A Johnson Matthey | MFCD00003436 (11391) | Gold foil, 0.004" thick |

| Transparency sheet | APOLLO | APOCG7060 | |

| Ultrasonic bath cleaner | Terra Universal | 2603-00A-220 | |

| Isotemp standard lab oven | Fisher Scientific | 13247637G | |

| Optical microscope | Fisher Scientific | 15-000-101 | |

| Tweezers | Technik | 18049USA (2A-SA) | |

| Surgical blade handles | Aspen Surgical Products | 371031 | |

| Base frame | McMaster-Carr | 9785K411 | |

| Support beam | McMaster-Carr | 9524K359 | |

| Two parts silicone | Nusil | MED 4765 | |

| Soldering Flux | SRA Soldering Products | FLS71 | |

| Tape | 3M Healthcare | 1535-0 (SKUMMM15350H) | Paper, hypoallergenic surgical tape |

| Spot welding machine | Unitek | 125 Power Supply with 101F Welding Head | |

| Laser cutting platform | Universal Laser Systems | PLS6.150D | 150 watts laser |