Comprehensive Compositional Analysis of Plant Cell Walls (Lignocellulosic biomass) Part I: Lignin

Summary

Plant biomass is a major carbon-neutral renewable resource that could be used for the production of biofuels. Plant biomass consists mainly of cell walls, a structurally complex composite material termed lignocellulosics. Here we describe a protocol for a comprehensive analysis of the content and composition of the polyphenolic lignin.

Abstract

Protocol

1. Cell Wall Isolation

- Grind roughly 60-70mg of air- or freeze-dried plant material with 5.5 mm stainless steel balls in a 2 ml Sarstedt screw cap tube using an iWall, a grinding and dispensing robot (30 s). An alternative non-robotic low-throughput procedure using a ball-mill (retschmill) is presented in Part II2.

- Add 1.5 ml of 70% aqueous ethanol to the dispensed ground material, and vortex thoroughly.

- Centrifuge at 10,000 rpm for 10 min to pellet the alcohol insoluble residue.

- Aspirate or decant the supernatant.

- Add 1.5 ml of chloroform/methanol (1:1 v/v) solution to the residue and shake tube thoroughly to resuspend the pellet.

- Centrifuge at 10,000 rpm for 10 min and aspirate or decant the supernatant.

- Resuspend pellet in 500 μl of acetone.

- Evaporate the solvent with a stream of air at 35°C until dry.

If needed dried samples can be stored at room-temperature until further processing. - To initiate the removal of starch from the sample resuspend the pellet in 1.5 ml of a 0.1 M sodium acetate buffer pH 5.0.

- Cap the Sarstedt tubes and heat for 20 min. at 80°C in a heating block.

- Cool the suspension on ice.

- Add the following agents to the pellet: 35 μl of 0.01% sodium azide (NaN3), 35 μl amylase (50 μg/mL H2O; from Bacillus species, Sigma); 17 μl pullulanase (17.8 units from Bacillus acidopullulyticus; Sigma). Cap the tube and vortex thoroughly.

- The suspension is incubated over night at 37°C in the shaker. Orienting the tubes horizontally aides improved mixing.

- Heat suspension at 100°C for 10 min in a heating block to terminate digestion.

- Centrifuge (10,000 rpm, 10 min) and discard supernatant containing solubilized starch.

- Wash the remaining pellet three times by adding 1.5 ml water, vortexing, centrifuging, and decanting of the washing water.

- Resuspend pellet in 500 μl of acetone.

- Evaporate the solvent with a stream of air at 35°C until dry. It may be necessary also to break up the material in the tube with a spatula for better drying.

The dried material presents isolated cell wall (lignocellulosics). If needed dried samples can be stored at room-temperature until further processing.

2. Lignin Content

This method is based on a reported method by Fukushima and Hatfield 3.

- Weigh 1 – 1.5 mg of prepared cell wall material (see 1) into 2 ml volumetric flask leaving one tube empty for a blank.

- rinse tube walls with 250 μl of acetone to collect the cell wall material on the bottom of the tube, and evaporate the acetone very gentle under airflow.

- Gently add 100 μl of freshly made acetyl bromide solution (25% v/v acetyl bromide in glacial acetic acid) along the tube walls to prevent splashing.

- Cap volumetric flask and heat at 50°C for 2hrs

- Heat for an additional hour with vortexing every 15 minutes.

- Cool on ice to room temperature.

- Add 400 μl of 2M sodium hydroxide and 70 μl of freshly prepared 0.5 M hydroxylamine hydrochloride. Vortex volumetric flasks.

- Fill up volumetric flask exactly to the 2.0 ml mark with glacial acetic acid, cap and invert several times to mix.

- Pipette 200 μl of the solution into a UV specific 96 well plate and read in an ELISA reader at 280nm.

- Determine the percentage of acetyl bromide soluble lignin (%ABSL) using an appropriate coefficient (Poplar = 18.21; Grasses = 17.75; Arabidopsis = 15.69) with the following formula:

% ABSL Calc:

Multiplication of %ABSL with 10 results in the ug/mg cell wall unit

It helps to do at least 3 plate reads to average the absorbance (abs) since particulates can cause a slight variation in absorbance values. Note: 0.539 cm represents the pathlength, but depending on the plate this might need to be determined.

3. Lignin Composition

This method is adopted from a recent method published by Robinson and Mansfield5.

- Transfer approximately 2 mg of cell wall material (see 1.) into a screw capped glass tube for thioacidolysis.

- carefully prepare the 2.5% boron trifluoride diethyl etherate (BF3), 10% ethanethiol (EtSH) solution. You must use a balloon filled with nitrogen gas to displace the lost volume in the dioxane bottle with nitrogen. Dioxane is very hazardous, do not take samples or equipment out of the hood. Volumes needed for the preparation of the solution per sample: 175 μl dioxane; 20 μl EtSH; 5 μl BF3.

- Add 200 μl of EtSH, BF3, dioxane solution to each sample.

- Purge vial headspace with nitrogen gas and cap immediately.

- Heat at 100°C for 4 hours with gentle mixing every hour.

- End reaction by cooling on ice for 5 minutes.

- Add 150 μl of 0.4M sodium bicarbonate, vortex

- For the clean-up add 1 ml of water and 0.5 ml of ethyl acetate, vortex and let phases separate (ethyl acetate on top, water on bottom).

- Transfer 150 μl of the ethyl acetate layer into a 2 ml Sarstedt tube. Make sure no water is transferred.

- Evaporate solvent by a concentrator with air.

- Add 200 μl acetone and evaporate (repeat for a total of two times remove excess water).

- For the TMS derivatization add 500 μl of ethyl acetate, 20 μl of pyridine, and 100 μl of N,O-bis(trimethylsilyl) acetamide to each tube.

- incubate for 2 hours at 25°C.

- Transfer 100 μl of the reaction into a GC/MS vial and add 100 μl of acetone.

- Analyze the samples by GC equipped with a quadrupole mass-spectrometer or flame ionization detector. An Agilent HP-5MS column is installed (30 mm X 0.25 mm X 0.25 μm film thickness). The following temperature gradient is used with a 30 min solvent delay and a 1.1 ml/ min flow rate: Initial hold at 130 °C for 3 min; a 3 °C/ min ramp to a 250 °C and hold for 1 min; allow equilibration to the initial temperature of 130 °C.

- Peaks are identified by relative retention times using tetracosane internal standard (optional) or by characteristic mass spectrum ions of 299 m/z, 269 m/z, and 239 m/z for S, G, and H monomers, respectively (see Fig. 2). The composition of the lignin components is quantified by setting the total peak area to 100%

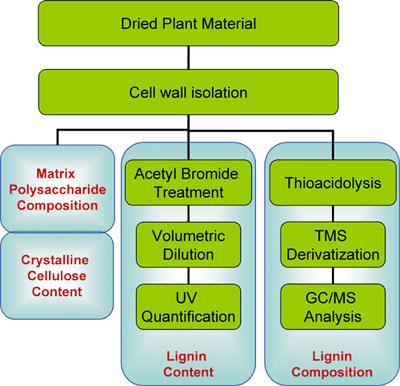

4. Representative Results

An example of a wall analysis is presented in Figure 2. In this case poplar stem (wood) was analyzed by the various procedures outlined in the protocol section. An example chromatogram of the separation of lignin-components after thioacidolysis and TMS-derivatization is shown. Clearly, the relative abundance of syringyl- (S), guaiacyl- (G), and p-hydroxyphenol- (H) units can be determined. The content of acetyl bromide soluble lignin is self-explanatory, one can expect values of between 20-50% of the wall dry weight. One should note that acetyl bromide does not solubilize all of the lignin present in the wall, and that the degree of solubilization can vary depending on the material. However, this method is relatively easy to carry out and rapid and gives an excellent approximation of the lignin content in a lignocellulosic material.

Figure 1: Overview of lignocellulosic analysis. Cell walls (lignocellulosics) are isolated from crude dried plant material. The wall material is then weighted into aliquots and subdivided for the various assays. Wall material is treated with acetyl bromide and the solubilized lignin quantified by UV-spectroscopy. For the determination of the lignin composition, wall material is subjected to thioacidolysis. The solubilized phenolics undergo TMS derivatization and can then be separated and quantified by GC-MS analysis. The matrix polysaccharide composition and crystalline cellulose content protocol is discussed in Part II2.

Figure 2: Comprehensive lignocellulosic analysis of poplar wood. Wood chips from poplar (Populus tremoloides) were subjected to the described protocols.

Ligin composition; H p-hydroxyphenyl ;G guaiacyl; S syringyl units.

Discussion

The described methods enable a rapid quantitative assessment of the lignin content and composition of lignocellulosic plant biomass. Using the iWall robot approximately 350 samples can be ground and dispensed per day. The throughput of the various analytical methods per person varies. Using the protocols described here, 30 samples can be processed for lignin content, and 15 for lignin composition per day. Due to the quantitative nature of the data optimal feedstock crops, variety or genotypes can be assessed in terms of their suitability for biofuel production.

Acknowledgements

We are grateful to Matthew Robert Weatherhead for excellent technical service and John Ralph, University of Wisconsin for valuable advice, discussions, and the poplar wood sample. This work was funded by the US Department of Energy (DOE) Great Lakes Bioenergy Research Center (DOE BER Office of Science DE-FC02-07ER64494) and by the Chemical Sciences, Geosciences and Biosciences Division, Office of Basic Energy Sciences, Office of Science, U.S. Department of Energy (award no. DE-FG02-91ER20021).

Materials

| Material Name | Typ | Company | Catalogue Number | Comment |

|---|---|---|---|---|

| Hydroxylamine Hydrochloride | Sigma-Aldrich | 255580 | ||

| Acetyl Bromide | Aldrich | 135968 | ||

| Ethanethiol | Sigma-Aldrich | E3708 | ||

| Borontrifluoride diethyl etherate | Fluka | 15719 | ||

| N,O,-Bis(trimethylsilyl) acetimide | Fluka | 15241 | ||

| Dioxane | Sigma-Aldrich | 296309 | ||

| Spectromax Plus 384 | Molecular Devices | Plus384 | ||

| GC-MS | Agilent | 6890 GC/5975B MSD | (lignin composition) | |

| 5.5mm Stainless Steel Balls | Salem Ball Company | (N/A) | ||

| 96 well plate heat spreader | Biocision | Coolsink 96F | ||

| Heating block | Techne | Dri-block DB-3D | ||

| Sample concentrator | Techne | FSC400D |

Referenzen

- Carroll, A., Somerville, C. Cellulosic Biofuels. Annual Review of Plant Biology. 60, 165-165 (2009).

- Foster, C. E., Martin, T., Pauly, M. Comprehensive compositional analysis of Plant Cell Walls (Lignocellulosic biomass), Part II: Carbohydrates. J Vis Exp. , (2010).

- Fukushima, R. S., Hatfield, R. D. Extraction and isolation of lignin for utilization as a standard to determine lignin concentration using the acetyl bromide spectrophotometric method. J. Agric. Food Chem. 49 (7), 3133-3133 (2001).

- Pauly, M., Keegstra, K. Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J. 54 (4), 559-559 (2008).

- Robinson, A. R., Mansfield, S. D. Rapid analysis of poplar lignin monomer composition by a streamlined thioacidolysis procedure and near-infrared reflectance-based prediction modeling. Plant J. 58 (4), 706-706 (2009).

- Somerville, C. Toward a systems approach to understanding plant-cell walls. Science. 306 (5705), 2206-2206 (2004).

- Teeri, T. T., Brumer, H. Discovery, characterization and applications of enzymes from the wood-forming tissues of poplar: Glycosyl transferases and xyloglucan endo-transglycosylases. Biocatalysis and Biotransformation. 21, 173-173 (2003).